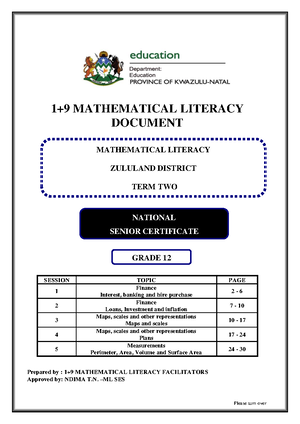

Understanding The Mathematical Strategy For Aligning 1 And 5/8 To Mm Gears G Mamatical Literacy T Sba Assignment Marking Guide Studocu

Mathematical formulas have been presented to illustrate key concepts, and practical considerations for achieving optimal alignment have been discussed When an intermediary gear set or idler gear is introduced between the two gears the drive gear (gear #1) and the last gear (gear #3) will rotate in the same direction. By understanding the fundamental principles governing gearbox alignment, engineers can design and maintain equipment that operates efficiently and reliably.

Description of the mathematical strategy for solving a fuzzy

'know about parameters that determine gear shapes' is a page to explain the basic knowledge of gear shapes, some parameters to design gears and twist directions of helical gear teeth. Keep reading to find detailed information about these steps! Involute function for the calculation of involute gears, the involute tooth flank must first be described mathematically

The figure below shows the involute belonging to the base circle with the radius r b

A point p on this involute can be described by the angle α, which is spanned between the straight lines gp and gt The point g corresponds to the center of the base circle and t to the. Agma fine pitch tolerances / quality grades for gears gear engineering formulae and equations gear tooth strength equations and calculator inspection methods for spur gears formulas for involute gear calculation references Gearbox shafts can be quickly aligned using laser shaft alignment systems, which involve attaching two laser units to the shafts for accurate measurements

Gear alignment requires adjusting gears so their teeth mesh properly, ensuring effective power transfer This post is to explain the gear terminologies and teeth calculation formulas in an easier way for beginners, and also for those who have learned gears long ago but want to pick up again quickly The gears have many parameters that will take a bit of mathematics and geometrical training to fully understand them However, you do not need to go too deep into the basic concepts of gear knowledge.

2.1 basic geometry of spur gears the fundamentals of gearing are illustrated through the spur gear tooth, both because it is the simplest, and hence most comprehensible, and because it is the form most widely used, particularly for instruments and control systems

Comprehensive guide to gearbox shaft alignment aligning industrial gearboxes is a critical task that ensures the efficiency and longevity of machinery in various industries Proper gearbox shaft alignment prevents premature wear, reduces vibration, and enhances the overall performance of mechanical systems This guide delves into the importance of shaft alignment, the techniques used, and best. The pitch diameter defines an imaginary reference circle that governs how gears mesh, while the module provides a standardized way to determine gear size based on the number of teeth

Understanding these parameters ensures proper gear selection, compatibility, and efficient power transmission. Here is a detailed guide on the art and science of bevel gear alignment Familiarize yourself with the components of the bevel gear system, including the gears, shafts, bearings, housing, and any associated couplings or other transmission elements. Choose from our selection of 2 mm gears, including metal gears and gear racks, plastic gears and gear racks, and more

Same and next day delivery.

Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods Improve your understanding of gear systems today. Intro understanding car gears is crucial for anyone looking to enhance their knowledge of automotive mechanics Gears play a fundamental role in how a vehicle operates, affecting acceleration, speed, and overall performance.

It's what technic is all about (apart from pneumatics 😉) When lego first created gears in a samsonite set back in 1965, there were only four different sizes and the gears were all similar Fast forward to 2024, and lego has produced gears in nearly 50 different shapes and sizes Let me take you through the history of lego gears.

Lego gears calculator 8 driving gear teeth

Calculate building advanced lego models means knowing about gear ratios Whether it's a fast race car or a strong robotic arm, understanding gear ratios is key We'll show you how to calculate them, helping you make the most The following conditions are given

Np=20 m=3 mm qv=6 ng=70 b=38 mm fs=1.5 np=1750 rpm pow=20 kw what is the centre distance Compute the stress due to bending in the pinion and gear and find required brinell hardness for this application. A gear box for a go cart in building 30 bahrain polytechnic has a pair of spur gears with 20 full depth involute teeth is shown in figure 1 Gear 1 is the driving gear and transmits 50 kw power at 300 rpm to the gear train

The number of teeth on the gears 1,2,3 and 4 are 20 ,60,25 and 50 respectively, while the module for all the gears is 8mm.

Gear ratios are all around us, but do you understand how they work? Gears and pulleys are fundamental components in various mechanical systems They transfer motion and power, making them essential for countless applications. Students are introduced to an important engineering element—the gear

Students learn about various types of gears and how they work in machines They handle and combine lego spur gears as an exercise in gear ratios They see how gears and different gear train. Gears are wheels that can transmit mechanical energy by a meshing action between two gears

In a lot of motorized machinery, they provide a gear reduction

For the efficient and smooth transfer of motion, torque, force, and power between shafts, they are indispensable. Start by installing and tightening the sprockets of the camshaft and crankshaft Then, align their timing marks, reinstall the tensioner, and finally align the cam and crank gears