The Viral Tech Debate: Integrated Smart Starters Versus Manual Motor Starters

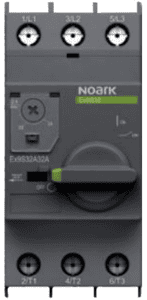

The strategic shift for modern industrial automation the decision between using a smart motor controller and a traditional starter is far more than a simple technological upgrade Noark's manual motor starters help control panel manufacturers meet the electrical code requirements for motor branch circuits by providing the required short circuit and overload. The motor starters combine motor control functions such as reversing or soft starting with monitoring functions such as motor protection function, phase monitoring, etc.

Accessories – Manual Motor Starters

They can provide precise control over the motor's speed and torque, ensuring consistent product quality and reducing production costs Manual motor starters (mmss) are designed to handle the high electrical currents that motors require and provide a convenient and reliable way to start and stop electric motors in machinery and control panels Conclusion smart motor starters are a critical component of modern industrial and commercial systems, offering enhanced functionality, performance, and reliability compared to traditional starters.

The landscape of industrial automation is constantly evolving, driven by the need for increased efficiency, enhanced control, and reduced downtime

Within this dynamic environment, smart motor starters are emerging as a crucial technology, replacing traditional counterparts with their advanced capabilities This essay will explore the reasons behind the growing adoption of smart motor starters. In episode 7, we're exploring the future of motor control, where contactors and starters don't just switch power—they communicate, predict failures, and integrate with your entire plant. This translates to a more responsive and exhilarating driving experience.

Learn how electric motor starters work, compare magnetic motor starters and manual motor starter options, and choose the right type for your application. Learn the key differences between motor starters and motor controllers, their functions, and when to use each for effective motor management. Understanding the application and what is critical for motor control in that application will help determine which starting method to use. The operator activates the starter, energizing the contactor, which allows power to flow to the motor

Monitoring and protecting the motor

The overload relay continuously monitors current If excessive current is detected, the overload relay trips the circuit, stopping the motor before damage occurs. Learn how a motor starter works, including manual vs Electromechanical starters, overload protection, and safety features after power loss.

Choose from our selection of manual motor starters in a wide range of styles and sizes Same and next day delivery. A soft start motor starter is also referred to as an rvs or reduced voltage starter This strategy operates by employing fluid, steel shots, or magnetic forces

Manual motor starters (mms) are protection devices for the main circuit

They combine motor control and protection in a single device. Eaton offers one of the broadest lines of enclosed motor starters engineered for global industrial and hazardous applications Greenheck offers motor starters for both single phase and three phase motors in commercial and industrial applications These include basic motor protection and advanced motor protection, smartstart™.

A combination starter includes a contactor, overload relay, and disconnect switch within a single enclosure. We provide starters with and without main disconnect devices, combination and noncombination and we offer a variety of available modifications Applications for pumps, hvac, contactors and ac motors. With advanced protection features like underload (dry run) detection and smartstart technology, you can feel confident that your taco pump is well protected from harmful operating conditions.

Choose from our selection of iec motor starters, including motor starters, enclosed motor starters, and more