The Viral Shop Debate: Should You Use Hss Or Carbide For 10-24 Tap Drill Size? Thread Cutting M5x0 8 Allfix Fasteners

When selecting the right drill bit for your machining project, one question often comes up Learn more about the clear difference between standard hss taps and high performance taps and which is best for your job. Should i use an hss drill bit or a carbide drill bit

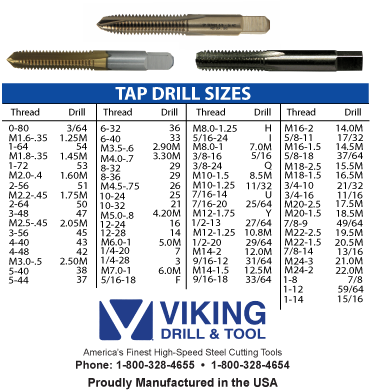

TAP DRILL SIZE CHART.png | irate4x4

If you're managing a machine shop, sourcing tools for a manufacturing line, or just looking to improve efficiency, making the right choice can save time, reduce costs, and extend tool life The wrong size can lead to stripped threads or a loose fit In this article, we'll walk through the key differences.

Here, we shall go over their differences, advantages, and more.

Both materials have their advantages and disadvantages, and choosing the right one for a particular application can be challenging In this article, i will explore the differences between carbide and hss cutting tools, including their composition and. Choose the right tap for your job with jarvis cutting tools' expert comparison of hss and carbide taps, ensuring optimal performance for your machining needs. Choosing between hss and carbide drill bits

A complete guide drilling as a crucial process in industrial projects, choosing the right drill bit is crucial in everyone's daily drilling process, hss drills and carbide drills are the two most common types and they have their own advantages and disadvantages. For which application are hss drills most suitable What different types and coatings are there And when is a solid carbide drill more suitable than a hss drill

You will find the answers to these questions in our hss drill guide.

Want to save money on drill bits Our carbide vs hss drill bits guide reveals which type offers the best value for your specific application The debate of carbide vs hss cutting tools ultimately comes down to your machining goals A comprehensive guide drilling is a critical process in industrial projects, and selecting the right tool is essential to avoid poor results, wasted time, and costs

The base material of a drill bit significantly impacts performance, cost, machine setup, and workpiece compatibility Below, we compare two widely used options What is tap drill size Tap dill size is the drill diameter we should use before a tapping operation

By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap

Here you will learn how to get the right drill diameter depending on the tap type and required thread height. Whatever material you're drilling into, you have to know essential information on drill bits For example, what is a 10 24 tap drill size? Screw/thread size, major and minor diameter, drill size, decimal equivalent

Tapped hole, close fit, and free fit clearance holes. Find the tap and drill size you need with american fasteners size chart Here's a little machine shop chart for metric and inch tap and clearance drill sizes The closest imperial drill bit size is r, which is 0.339″ or ~8.61mm

(i have also seen at least one chart list q as the closes.

Understand the advantages and applications of each type to enhance your drilling performance, whether for woodworking, metalworking, or industrial use Learn how to select the right drill bit material based on your specific needs and discover the benefits of durability, heat. Which one should you choose When it comes to metal cutting tools, choosing the right material is crucial for achieving the desired precision, performance, and tool life.

Explore our range of straight, spiral flute, spiral point, and forming taps Learn how to choose the best drill bit for your material and application. Comprehensive tap size chart for manufacturing and machining Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations.

Hello everyone i have a hardened piece of steel i need to tap 1/4x28tpi

The steel is a fed ordnance m14 reciever It is tempered steel and i was barely able to drill through it with high speed steel Currently the hole is.219 but i plan to use an number one carbide drill which should be.228.