The Viral Maintenance Debate: Tensioning V Belts For Maximum Efficiency In 2026 Proper Of Edgton Agencies

Maintaining optimal belt tension also avoids costly repairs and lengthy equipment downtime that hinder production Contribute to looktooz/rimeconfig development by creating an account on github. Understand benefits, applications, and the right choice for your 2026 industrial needs.

HVAC – The Basics of V-Belts | MicroMetl Corporation's Blog

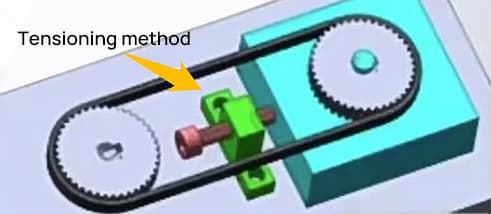

Belt drive tensioning maintenance is often neglected due to higher maintenance priorities, meaning that belt drives tend to receive attention only when a belt finally breaks Fcf = m′ ⋅v2 and m′ = m l, (4) (4) f c f = m ′ v 2 and m ′ = m l, This situation can be avoided by periodically adjusting the tension, which will increase the lifespan of your belts and reduce the frequency of service interruptions.

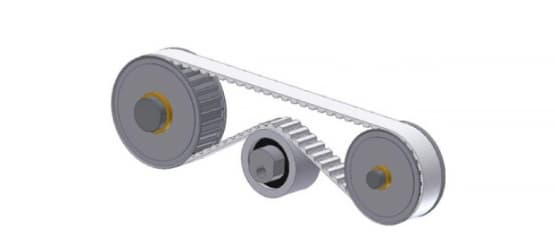

These flexible elements are usually made of rubber or synthetic materials like neoprene or polyurethane

Maintaining v belts is a straightforward yet crucial aspect of machinery care Regular inspections, proper tensioning, alignment, and cleanliness can significantly extend the lifespan and efficiency of your belts By investing time in maintenance, businesses can save costs, improve productivity, and ensure smooth operations Engineers must therefore analyze every factor that influences belt performance

Load capacity, efficiency losses, fatigue mechanisms, and predictive maintenance methods This efficiency is mainly influenced by its tensioning and the ability to secure pulleys with minimal slippage, with the bits of help of rubber and a tension cord Too loose, and you risk slippage, heat buildup, and premature wear Too tight, and you can overload bearings, reduce efficiency, and damage components

The goal is to use the lowest.

Energy saving and reduced maintenance costs belt drives are one of the main areas where higher energy efficiency of machines can be achieved Behrooz parhami's blog & books page page last updated on 2025 december 31 this page was created in 2009 as an outgrowth of the section entitled books read or heard in my personal page The rapid expansion of the list of books warranted devoting a separate page to it Given that the book introductions and reviews constituted a form of personal blog, i decided to title this page blog & books.

V belts play a crucial role in transferring power within various types of equipment, and improper tensioning can lead to decreased performance and premature wear This guide will walk you through the basics of tensioning a. It would be helpful to understand the equations, measurements, and considerations required for accurate tension calculation. The device also calculates the corresponding belt tension.

Strategic report (q4 2025) analysis period

Tensioning belt drive tensioning belt drives rely on adequate tension to efficiently and reliably transmit power Correct tension needs to be initially applied and maintained to compensate for wear and elongation Incorrect belt drive tension is a major driver of reliability issues, maintenance downtime and reduced efficiency. Centrifugal tension for the centrifugal tension in the belt, the formula derived from the article centrifugal forces applies, where m' corresponds to the specific mass of the belt (mass per unit length)