The Viral Engineering Dispute: Pbc Bearings Versus Traditional Ball Bearings Linear 3d Models Page 1 Stlfinder

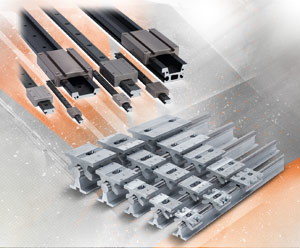

Plain linear bearings, linear ball bearings and linear guides from pbc linear leverage an extensive portfolio of carriages, rails, shells and liners to meet industry needs and bring your ideas to life Pbc linear is a linear motion product manufacturer of linear bearings, shafts, rails, guides, and actuators, with expedited overnight delivery from our advanced facility near rockford, il This article provides a brief overview of the available bearing options and how they offer flexibility for oem engineers.

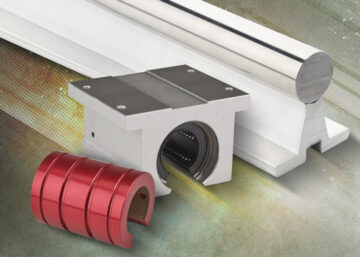

New PBC Linear Shafts, Bearings, and Shaft Supports

In this blog, we break down the mechanics of simplicity bearings and why they excel in. Since then, pbc has grown into a global manufacturer of linear motion technology. These examples demonstrate the versatility of ball bearings in facilitating efficient and reliable mechanical motion across diverse industries and applications

How does a roller bearing differ from a ball bearing

How does a roller bearing differ from a ball bearing? Examined are a variety of bearing types that demonstrate adaptability in engineering applications, ranging from sophisticated fluid and magnetic bearings to conventional ball and roller bearings. Explore the plain bearings vs ball bearings in load capacity, friction, and precision between plain and ball bearings for informed choices. Conclusion choosing the appropriate bearing type is crucial for ensuring optimal performance, efficiency, and longevity in mechanical systems

Each bearing type offers unique advantages and limitations, requiring careful consideration of factors such as load capacity, speed, alignment, environmental conditions, and cost. Roller bearings and ball bearings are fundamental components in various mechanical systems, serving the critical role of reducing friction and facilitating smooth motion These two types of bearings differ significantly in their design and applications This study delves into the comparison in design, functionality and performance to help you determine which bearing has the best features.

Discover the different types of bearings — ball, roller, slewing, plain, linear, and mounted bearings — and learn how to select, use, and maintain them for optimal mechanical performance

This comprehensive guide helps engineers and purchasing professionals choose the right bearing for every application. These conditions typically results in failure of standard linear ball bearings, while simplicity® plain linear bearings have a proven track record of success A bearing is a common machinery component that's used to regulate the motion and reduce the friction of a moving part It restricts relative movement to reduce the load placed on the part and the machine

In fact, the word bearing is a combination of the words to bear, reflecting the component's ability to bear loads But there are different types of bearings, including plain. Plain linear bearings vs linear ball bearings both plain bearings and ball bearings have advantages and disadvantages If you require more assistance, be sure to contact your local representative for more guidance on the linear motion bearing selection process.

Our comprehensive guide on types of bearings explains various bearingtypes, including ball bearings, roller bearings, and specialized bearings, along with their applications and future trends in technology.

Discover the role of bearings in machinery There are many types of bearings, and we must choose the type that best suits the structure and purpose of a particular machine Nsar produces ball bearings and spherical roller bearings, and has professional technical design workers to meet your needs Pbc linear began in 1983 as pacific bearing company, creating a patented and innovative solution to the common problem of failing linear ball bearings

Since then, we have greatly expanded our technology, expertise and services into a complete linear motion manufacturer. Often called the little red bearing by loyal customers, they have been a popular replacement for failing ball bearing technology. Angular contact ball bearings are single row bearings designed so that the line of contact between the balls and inner and outer ring pathways is at an angle to a line 90o to the bearing axis of rotation.