The Viral Engineering Dispute Over 1-5/8 To Mm Tolerances In Public Works Prt Readg And Lerances Trag Gd&t Basics

Maximum deviation of 3.2 mm if allowed tolerances on linear sizes a variations in the indicated dimensions for center to face. Similarly, deviations over longer wall surfaces would be unacceptable if the deviation exceeded 4 mm within any 2 m length of that surface. Some tolerances come from title 210 national engineering handbook, part 645 construction inspection, construction specifications (cs), some from astm international's (astm) standards used for testing, and still others from common usage or accepted practice within the construction industry.

Sheet Metal Tolerances: The Key to Precision Engineering | MachineMFG

The maximum limits of tolerances listed below do not necessarily represent total construction acceptability, but are limits at which the department may consider construction tolerances acceptable The tolerance cannot be interpolated to mean a 2 mm deviation over a 1 m wall surface or 1 mm deviation over a 500 mm wall surface It is intended that, in general, all work and materials be well within the tolerances given.

Any tolerances given in a contract, either directly or by reference, take precedence over generally accepted tolerances

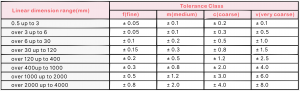

The qa inspector shall consult with the project engineer whenever there. In europe and many other parts of the world, general tolerances for subtractive manufacturing (such as cnc machining) are primarily defined by two key iso standards Iso 2768 and iso 286 Iso 2768 provides general tolerances for linear and angular dimensions when specific tolerances are not indicated on the engineering drawing.

Within tolerance construction can't be perfect all the time, so allowable tolerances have been defined to maintain quality Here are some of the key tolerances you should work to in order to ensure quality buildings. It applies for the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. Geometric tolerances, limits fits charts, mechanical tolerances tables and calculators

Maximum shaft size is taken as the basic size, an allowance is assigned, and tolerances are applied on both sides of and away from this allowance.

Tables of permissible deviations for external and internal sizes, distances, external radii, chamfer heights and broken edges in tolerance classes f, m, c and v. Pipe tolerances specified by asme b36.10/36.19, pipes diameter tolerance, pipes thickness tolerance, pipes length tolerance, pipes weight tolerance, pipes quantity tolerance. Wrench openings table for hex and square nuts per Depth variation is addressed in clause 7.22.9

For welded beams and girders, the maximum allowable variation from specified depth measured at the web centerline shall be for depths up to 36 in [1 m] incl ± 1/8 in [3 mm] for depths over 36 in [1 m] to 72 in [2 m] incl ± 3/16 in [5 mm] for. A 1.1 steel bars inches / millimeters max carbon content 0,28 % carbon content over 0,28 % and up to 0,55% size tolerances

Browse cold rolled steel tolerances over/under specifications to find the right size and material for your next project at onlinemetals.com.

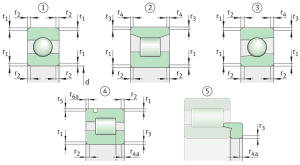

Recommended housing fits for radial bearings (classes 0, 6x, 6) 1) light, normal, and heavy loads refer to those with dynamic equivalent radial loads (pr) of 5 % or lower, over 5 % up to 10 % inclusive, and over 10 % respectively in relation to the basic dynamic radial load rating (cr) of the bearing concerned. Asme b1.1 inch size un external screw threads formulas and calculator per Asme b1.1 ansi/ asme external screw thread size chart

Engineering tolerances are essential aspects of new product development This article describes everything you need to know about engineering tolerance. Asme b18.2.1 covers length tolerance chart for inch series bolts and screws Tolerances are a crucial part of engineering to ensure the necessary precision

Learn about everything from linear tolerances to gd&t.