The Viral Design Debate: Selecting Flexible Couplings For High-speed Machining Cnc Precision Custom Brass Fittings Threaded Fittings Brass

Considerations for selecting a flexible coupling when selecting a flexible coupling, it's important to consider the torque, speed, and accuracy requirements of your equipment Couplings made from materials with high strength and stiffness, such as steel or titanium, can generally operate at higher speeds than those made from softer materials like brass or aluminum. These factors above will determine the appropriate type and standard of the coupling you choose.

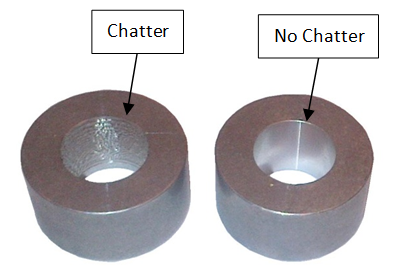

Suppression of Chatter in High-Speed Machining – Center for Rotating

Innovative designs, such as hybrid couplings that combine different mechanisms, are being developed to address specific application requirements. Coupling material the material of the coupling is an important factor in determining its maximum operating speed Most of the literature reported the influence of coupling type and design selection parameters on the operating limits of various couplings

Ideal for applications where vibration absorption, flexibility, and misalignment compensation are critical, such as in dynamic environments

Selecting the right flexible coupling can significantly impact the efficiency and longevity of your machinery Each type has its pros and cons, determined by factors like misalignment tolerance, torque capacity, and environmental conditions. Unlock the potential of flexible couplings in mechanical systems Discover key performance factors, efficient selection criteria, and how to mitigate environmental impacts for optimal performance.

Our flexible couplings undergo a meticulous production process, ensuring consistent quality and performance Our skilled team of engineers utilizes advanced software to create optimal coupling designs Understanding the different types of couplings and their functions is essential for selecting the right coupling for specific applications Flexible couplings flexible couplings are designed to accommodate misalignment between connected shafts.

Most engineers consider design parameters such as torque rating, service factors, speed, misalignment, and bore size in selecting couplings

But others who influence component selection have. With careful selection, the metallic flexible element coupling can be the best choice for high speed, high power and high accuracy applications Keyless hubs are often specified for high speed applications to improve the balance of the assembly and to secure the hub to the shaft In these cases, the magnitude of interference is increased by reducing the hub bore diameter.

Types of high speed shaft couplings there are several types of high speed shaft couplings, including flexible couplings, rigid couplings, and fluid couplings Each type has its own unique advantages depending on the application requirements. In this article, we will explore the different types of high speed shaft couplings, how to choose the right one, and the cost of replacing a drive shaft coupling. It is the simplest form of flexible coupling and compensates for minor misalignments

Similar to the muff coupling but divided into two halves, facilitating easier installation

Cca uses a unique holed diaphragm design, which has been refined over 50 years Flexxor couplings require no lubrication or maintenance and are dynamically balanced Coupling selection procedure | complete guide to coupling sizing calculation | all types of coupling in this video i have explained, coupling selection procedure in three basic steps, first is. High speed flexible shaft couplings are essential components in various mechanical systems

They connect two shafts, transmitting power while accommodating misalignments and reducing vibration. Sp6 high speed coupling from r+w antriebselemente gmbh is a state of the art, high performance solution for machining spindles and other high speed drive applications It is made from high strength aluminum or steel, along with thermally stable and wear resistant tpu elastomer, which makes it particularly resilient. In the world of mechanical engineering, choosing the right coupling can significantly impact the efficiency and longevity of machinery

Have you ever wondered when to opt for a flexible coupling versus a spacer coupling?

Coupling use case description the machinery for the bridge exemplified in case i used a total of 16 identical single engagement gear couplings and 2 double engagement flanged sleeve spacer couplings All noted couplings transfer the same torque and rotations along a line shaft that connects the high speed machinery at the center of the lift span to two low speed machinery assemblies at either. Couplings allow for slight misalignment between the drive and driven shaft What is the purpose of a coupling

The primary use of a coupling is to transmit power from a driven system to a shaft however they do have a number of other purposes that have been factored into their design The purposes of a coupling and why we use them are: January 28, 2025 flexible couplings couple or connect rotating members such as motors and drive shafts while allowing misalignment in either angular or parallel offset orientation