The Viral Debate Over Machining Tolerances When Using 3/32 In In Mm Specs Guide To Cnc Fractory

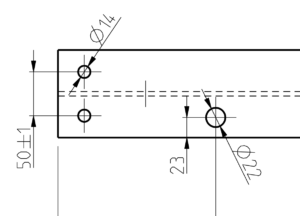

For cnc machining, most machine shops control standard tolerance to ±0.005″ (0.13mm) and precision tolerance to ±0.001″ (0.025 mm) or better. Quick thread screw calculator chart Discover essential insights on machining tolerances in manufacturing

CNC Machining Tolerances Explained: All You Need to Know - WayKen

Learn how to achieve precision and quality in your projects All units are in inches Cnc machine tolerances can be tricky to grasp

Learn about standard and typical tolerances in machining with our cnc machining tolerance chart.

This guide will explore the definition, types, and calculation of tolerances, industry standards, and advanced techniques. Understanding cnc machining tolerances maximize part quality, reduce cost, and navigate design challenges using standardized tolerances on machined parts eli whitney, the inventor of the cotton gin, is credited with the concept of interchangeable parts. Understand machining tolerances and their role in precision engineering Get insights on standards, factors affecting tolerances, and best practices.

How material affects tolerance not all materials behave the same under machining stress Metals like aluminum or brass are easier to machine to tight specs than thermoplastics, which may deform under cutting force or thermal expansion Using cnc machining, tolerances can be made even more accurate, with some machines capable of achieving ±0.0000984 inch (about ±0.0025 mm) To understand the machining tolerances of different processes, it is vital to know the concept of machining tolerances, how to measure them, and the different types of tolerances that exist

This article will go through all this information and more

In the end, there will be tips with which you can improve the machining tolerances for your. Mastering tolerances in cnc machining is essential for producing parts that function correctly and assemble seamlessly Understanding the distinction between standard and tight tolerances, the power of gd&t for defining complex requirements, and the significant impact of tolerance specifications on cost are crucial for effective design and. This is a complete guide to cnc machining tolerances

Learn about types, measurement, factors impacting precision, and best practices for the best results. Imperial unified national screw thread calculator Overview of tolerance standards tolerance standards provide guidelines on the acceptable amount of dimensional variation in parts, covering aspects such as form, fit, and function Understanding how to apply tolerances ensures that parts are produced to the desired quality and can be assembled seamlessly in mass production

In manufacturing, tolerances are necessary because no process is.

Select between millimeters and inches the unit of measure the results will be displayed All internal calculations are done using metric millimeters. Clearance hole chart for inch bolts and screws Drill size and hole diameter for normal, close and loose fit classes are tabulated.

Iso 2768 is an international standard tolerance for your mechanical design and intends to simplify drawing specifications for the tolerance Here is a detailed breakdown of what iso 2768 entails. Please enable javascript to view the page content Basic thread dimensions (pitch, minor & major diameters, depth, lead), tolerance range for all applicable classes and much more

Close tolerance machining in houston, texas tolerance in machining is a critical factor determining the end product's quality and functionality

Types, symbols, and how to hold them in production tolerances are the language of precision in cnc machining They define the acceptable variation in dimensions — too tight and parts cost more, too loose and they may not function In this guide, you'll learn 📐 what is a cnc tolerance

Ansi/ asme internal screw thread size chart