The Viral Debate Over 7/16 In Mm Tolerances In Automated Assembly Lines Fully Les And Maches Kemach

Explore how assembly line automation integrates robotics, control systems, and smart technologies to boost efficiency, quality, and flexibility in manufacturing! Types of production line layouts Component placement challenges in pcb assembly don't have to slow you down

Fully automated Assembly lines and Machines – kinemach

Automated lines, with their focus on automated component placement accuracy, automated component placement machine calibration, smt component placement tolerance, and pick and place machine precision, offer reliable solutions for electrical engineers. It is technologically impossible or economically infeasible to automate the assembly process Automated assembly lines offer consistent accuracy that manual processes simply cannot match

Many automated systems achieve tolerances of ±0.01 mm, which is critical for complex assemblies like circuit boards, medical devices, and automotive engines.

The creation of rules will require specialist skills However, only a small group will require these skills as once created, application within design is simple. Accelerating manufacturing innovation with design for automated assembly simulated designs perform more like real products and drive a feedback loop of continuous improvement. Understanding cnc machining tolerances maximize part quality, reduce cost, and navigate design challenges using standardized tolerances on machined parts

For parts with moving assemblies or mating fits Often ±0.02 mm or tighter Go beyond dimensions to control form orientation, location and runout Knowing which one to use (and where) is essential to balancing cost and functionality.

Optimizing automated assembly lines for efficiency the landscape of automation machinery manufacturing is evolving rapidly

With the advent of advanced business intelligence and data analytics, assembly technicians now have unparalleled access to data that can drive enhancements in assembly line reconfiguration In a world driven by speed, precision, and scalability, assembly automation is no longer a luxury—it's a competitive necessity At adaptive innovations, we've seen firsthand how thoughtful automation unlocks real. This article introduces the types of assembly lines, the basic advantages, and the characteristics of assembly line systems.

Slip fit & press fit guide Understand tolerance chart fits, interference fit, slip fit, shaft alignment, and ansi standards. We're on a journey to advance and democratize artificial intelligence through open source and open science. 1/64 1/32 3/64 1/16 5/64 3/32 7/64 1/8 9/64 5/32 11/64 3/16 13/64 7/32 15/64 1/4 17/64 9/32 19/64 5/16 21/64 11/32 23/64 3/8 25/64 13/32 27/64 7/16 29/64 15/32 31/64 1/2

Automated assembly lines are a fundamental part of today's manufacturing industry

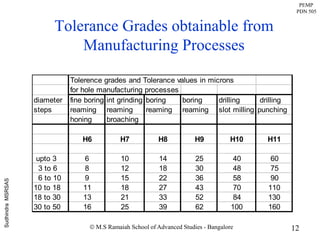

Due to shortening product life cycles and an increasing number of product variants, assembly lines have to be designed with increasing frequency Currently, all design decisions are based on the knowledge and expertise of engineers and the design process results in a high amount of manual effort 📉 sap mm delivery tolerances explained | overdelivery & underdelivery tolerances in purchase orders in this video, we dive deep into delivery tolerances in sap mm, focusing on overdelivery and. Tolerances and fits guide for every mechanical engineer, master tolerances and fits to boost design accuracy, ensure perfect part fit, and elevate your mechanical projects.

Cable assembly tolerances common cable assembly tolerances adopting the length tolerances shown in the table below minimizes cable assembly manufacturing costs The tolerance recommendations apply for overall cable assembly length and for branch lengths of complex assemblies with multiple breakouts. If tolerance for reamed holes is h8, that's +0/+0.00071. Automated assembly lines refer to production systems that utilize machines and automatic equipment to perform tasks, often in conjunction with human operators who may assist minimally by loading or unloading materials

This article will explore the key tolerance standards used in subtractive manufacturing, specifically iso 2768, iso 286 and gd&t.

This blog provides a guide to the most common types of automated assembly machines and how amd can meet your needs with custom automation equipment. High or medium demand for product 2 Identical or similar products 3 Total work content can be divided into work elements 4