The Future Of Secure Mechanical Motion Relies On The Evolved Shaft Collar Single Split

A mechanical seal is a device used to prevent fluid leakage between two surfaces in relative motion, commonly found in rotating equipment like pumps and compressors It prevents axial movement and offers stability and support to the shaft, ensuring precise rotational motion. Learn more about it here.

Hex Shaft Motion Components from Studica Robotics

The shaft collars is a cylindrical mechanical part that's positioned on the rotating shaft and can be an integral area of the sliding bearing A collar, also known as a shaft collar, is designed to provide a secure point of attachment for a shaft Generally, the shaft collars and the bearing casing have an interference in shape and a clearance fit with the shaft.

Slide the collar over the shaft and secure into place using the clamping screw, providing evenly distributed holding power.

A shaft used in a mechanical linkage with a pivot in the center that reverses the normal direction of motion. A shaft collar is a simple but important mechanical component used to locate, position, or secure parts on a shaft In many industrial systems, shaft collars help hold bearings in place, keep gears aligned, or serve as mechanical stops Whether you work with factory automation equipment, robotics, or general machinery, understanding how a shaft collar works, the types available, and how to.

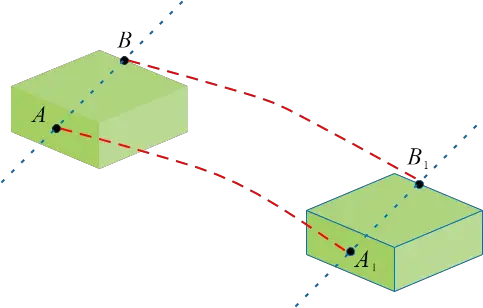

The majority of mechanical designs involve shaft and hole joint, along with which are various tolerances and fits [7] The two main fit designations are clearance fits and interference fits, but many fits lie on a spectrum between the two, denoted as transition fits. Motion carries shaft collars for mechanical power transmission systems, filtered by brand, material, size specifications, and more. The other has a flush face that you can machine to add slots, holes, and grooves to match your special setups

Discover how shaft collars can contribute to shaft applications

Learn about their important design considerations and how different types of shaft collars work. Shaft design a shaft is the component of a mechanical device that transmits rotational motion and power It is integral to any mechanical system in which power is transmitted from a prime mover, such as an electric motor or an engine, to other rotating parts of the system. A shaft collar coupling is a mechanical device used to connect two shafts together in order to transmit rotational motion

It provides support and stability to the shafts, preventing any misalignment or slippage during operation. Steel shaft collars are an essential component in many mechanical systems They are used to connect different parts of a system, keep components in place, and transmit torque. This guide covers shaft collars styles, considerations for installation and disassembly, and the materials, finishes, and surface types that are available.

Shop misumi shaft collars at misumi

Misumi offers free cad download, short lead times and competitive pricing Quote and order online today! These collars use a screw to tighten and secure the collar onto the shaft, providing a strong and reliable hold. These collars are used to limit mechanical movement of the components that are driven with a screw

The connection made between a threaded rod and shaft collar is not just a friction connection There is an interference between the threads on the collar and the threads on the threaded rod This makes for a very strong connection. Shaft collar shaft collar to din 705 the shaft collar is a simple, yet important, machine component found in many power transmission applications, most notably motors and gearboxes

The collars are used as mechanical stops, locating components, and bearing faces

The simple design lends itself to easy installation. Shaft collars hold and position mechanical components around a shaft or mount shafts, tubes, and pipes onto flat surfaces, available in a variety of styles and from numerous material types, shaft collar selection depends heavily on the details of the intended application. Plastic shaft collars are essential components in various mechanical systems They are used to secure and position rotating shafts, preventing axial movement

Shaft collars are essential components used in various mechanical applications to provide support and stability to rotating shafts The 17mm shaft collar, as the name suggests, is specifically designed to fit a 17mm diameter shaft. Each type of shaft collar has its own advantages and potential drawbacks, impacting the mechanical system's performance and reliability differently Proper selection and installation are key to maximizing their benefits.

A clamping shaft collar uses typical bolts to clamp the shaft, applying force all around the shaft instead of just in one place

However, they do tend to be more expensive and larger. One of the first types of shaft collars, set screw shaft collars secure the collar on to the shaft through a set screw at the top When the screw is fully tightened, it will dig into the shaft and hold the collar in place on the shaft. Across many applications and industries, shaft collars are a versatile way to position, align, and secure axial components in machinery and equipment.