Taper Lock Bushing: New 2026 Standards For High-torque Precision Mounting 1615 Bushing

This ensures interchangeability among products from different manufacturers This bushing uses set screws to fasten the bushing to the. Similarly tighten remaining screws in an alternating pattern while checking that the bushing surface at the split line remains even

Used Taper Lock Bushing for sale. Dodge equipment & more | Machinio

After partially tightening all screws, repeat this process tightening screws to the full recommended torque When dismounting the bushing is necessary, the bolts are taken out and screwed into the threaded holes to disassemble the parts Taper bushing is a new type of component part used forjointing mechanical transmission

The grip is tightened through its taper surface, excellent concentricity and nonclearance joint, its transmission e ciency can be raised.

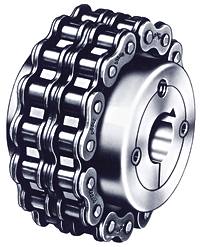

They provide easy mounting of pulleys, sprockets, and other rotating components, ensuring excellent durability and efficient torque transmission. Where bushing is used with lubricated products such as chain, gear or grid couplings be sure to seal all pathways (where lubrication could leak) with rtv or similar material. For a double split taper bushing to function correctly, both the internal and external keys must be aligned properly before tightening the bolts Shop inch and metric taper lock bushings for secure shaft mounting

Browse size charts and find the right taper lock solution for your equipment. Your belt systems demand high power rotational or linear movement, without any added friction or handling stress That's where gates bushings come in, bringing speed, efficiency, and reliability to your industrial, commercial or automotive belt drive applications Introduction to taper bushings taper bushings, also known as taper lock bushings or simply taper sleeves, are mechanical components widely used in power transmission systems

They provide a secure and convenient method for mounting pulleys, sprockets, and other components onto shafts

What is a taper bushing? Roller chain sprockets reliably handle high shock loads and deliver large amounts of torque Same and next day delivery. The most precise methods of fixing gears on a shaft include taper lock bushings, taper and friction fits, and high precision splines, but these add cost and make assembly more difficult

Set screws and keys are excellent solutions for many gear applications, but must be carefully used to avoid excessive wear or noise. High torque capacity taperlock couplings are capable of transmitting high levels of torque, making them suitable for demanding industrial applications The tapered interface between the hub and bushing ensures a uniform distribution of torque along the entire length of the coupling, reducing stress concentrations and improving overall performance. Alternately torque set or cap screws* to recommended torque setting in chart below

On 3535 and larger bushings use a block, sleeve or drift and hammer large end of bushing (do not hammer bushing directly)

Repeat steps 4 and 5 until torque wrench reading, after hammering, is the same as before hammering Fill all unoccupied holes with grease. Includes complete dimensional data for bushings and hubs from size 1008 through 120100. Find taper lock bushings manufacturers, suppliers, dealers & latest prices from top companies in india

Buy from a wide range of taper lock bushings online. The taper lock bushing is manufactured from precision cast iron.,and is machined to a high quality finish Taper lock bushes are essential components used to mount pulleys, sprockets, and gears securely onto shafts Designed with a tapered bore, they provide a strong grip, reduce shaft wear, and allow for quick installation or removal.