Surprising Torque Data: How The New Ac Motor Models Are Beating Dc Performance To Mere Bl Curve Infoupdate Org

Why do engineers prefer dc motors for precise speed control and strong torque The voltage can be directly connected to a strip chart as described previously to measure the motor acceleration, a second test output provides a dc voltage proportional to torque or a percentage of rated torque. When comparing dc vs ac motors, they handle these aspects differently

Electric Motor Torque Calculator

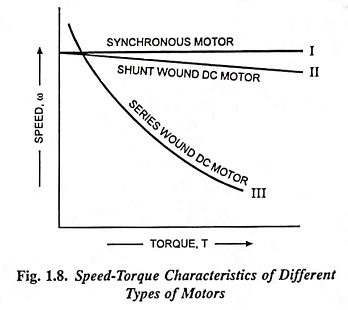

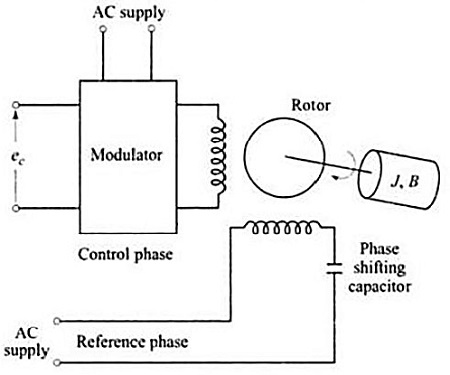

Dc motors have a direct relationship between voltage and speed, making them ideal for applications like conveyor belts or elevators For improved readability of block diagrams, each simscape domain uses a distinct default color and line style for the connection lines. On the other hand, ac motors require specialized control equipment to achieve similar performance

Compare ac vs dc motors with this expert guide

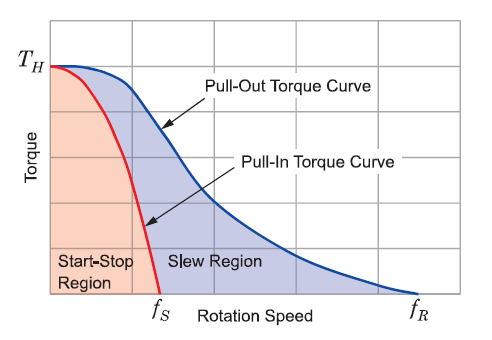

Learn key differences, features, advantages, and how to choose the best motor for your application. Critical parameters are typically starting torque (torque at zero rpm), and peak/maximum power and the corresponding rpm Ac motors dominate industrial applications (90%+ market share) due to lower cost, minimal maintenance, and robust construction Dc motors excel when precise speed/torque control is critical without vfds

Modern vfds have largely eliminated dc motor advantages, making ac induction motors the default choice for new installations. Compare ac vs dc electric motor basics, torque, control & cost—plus faqs Practical ac vs dc motor solutions for industrial applications. Compare ac and dc motors on performance metrics such as torque and rpm to find the right fit for your application.

Why is the starting torque of a dc motor greater than that of an ac motor

Dc (direct current) motors generally have higher starting torque compared to ac (alternating current) motors Explore the key differences between ac motors and dc motors, including efficiency, speed control, maintenance, and applications Learn which motor fits your needs best. When selecting an electric motor for industrial, commercial, or home applications, a common question arises

Is an ac motor stronger than a dc motor? understanding the characteristics of alternating current (ac) and direct current (dc) motors is essential to make an informed decision Power and torque comparison dc motors Dc motors are known for delivering Search model trained on march 2025 | vector size

This is a crucial topic in motor selection and understanding their behavior

I'll organize this into sections Dc motors, ac motors (induction & synchronous), and then a direct comparison table at the end. • the motor this is why robotics use current sources䢉䩪 = τm bearings torque is proportional to motor current want to directly input motor torque ki is a motor constant ki=kb (in si units) Choose from our selection of electric motors, dc electric gearmotors, and more

Same and next day delivery. Custom dc motors give us a call with your vehicle specifications and requirements Our current design capabilities are In the usa, you will know if it is a dc motor model because the motor is reported in hp instead w

Costco used to carry a dc motor model, but they don't anymore and haven't for a while

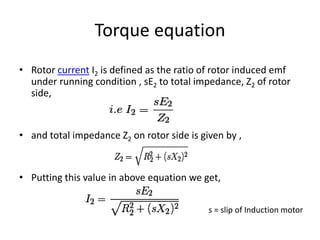

The current costco model, a professional 610 in disguise, uses a 590w ac motor The only dc motor models are: In general, the torque generated by a dc motor is proportional to the armature current and the strength of the magnetic field In this example we will assume that the magnetic field is constant and, therefore, that the motor torque is proportional to only the armature current by a constant factor as shown in the equation below.

The speed of a brushed dc motor can be controlled by changing the voltage alone By contrast, an ac motor is powered by alternating current (ac) which is defined by both a voltage and a frequency Consequently, motors that are powered by ac require a change in frequency to change speed, involving more complex and costly speed control. Brushless dc motors exhibit reduced energy use, long life, low noise, compact size and light weight characteristics

Brush dc motors have various advantages such as high efficiency, potential to downsize, ability to run on electric power, and low manufacturing costs

However, these motors have a. The torque is the twisting force that makes the motor running and the torque is active from 0% to 100% operating speed. Starting today, there are around 20 sorts of dc and ac motors that all effectively convert electrical energy to mechanical energy Out of these brushless dc motor is picked given their higher sturdiness because of effortlessness in outline and fast capacities

The model contains a dc motor subsystem with two electrical and two mechanical rotational ports