Surprising Data: How Fenner Drives Reduced Belt Installation Time By 70 Percent Essepienne

Did you know that 70% of friction drives are incorrectly installed Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on youtube. That figure is quite astounding particularly when you consider how many applications are dependant on the efficiency and reliability of friction belt drives.

V-BELTS HVAC - B-LOK KEYLESS LOCKING DEVICES -SHRINK DISKS- HUBS

Reduced dusting drives running at designed parameters means less dust caused by belt slip. Shop fenner drives 0410050 and trust mro to be your reliable fenner drives supplier to experience the difference that quality and expertise can make Fenner drives engineers and maintenance personnel trust fenner drives belts, keyless bushings, pulleys, and tensioners for their power transmission and conveying applications

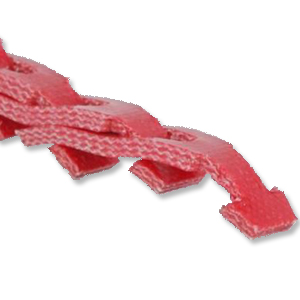

Powertwist drive is installed in basically the same way as the original powertwist link belting

However, belt length measurement may differ somewhat Force deflection data charts are included in the installation instructions to ensure proper tension Like all powertwist products, powertwist drive drops right in to existing pulley setups. Having the right belt on hand saves you time & money

It comes in the same standard cross sections as rubber belts, and you can make a belt any length you need by hand in seconds. Fenner drives, a division of fenner plc, is a manufacturer of link belting products, keyless locking devices, tensioners, pulleys, idlers, guides, and belting accessories This can cause energy losses for belt and chain drives In addition, incorrect belt or chain tension will lead to increased downtime, lower equipment productivity and inflated maintenance costs.

Purchased by michelin in 2018 and integrated into their polymer composite solution group, we have combined our agile service and michelin's technical resources to drive innovation.

For best results, count # of links, note For drives with multiple belts, then check final tension with force make sure each belt has matching deflection gauge after installation View & download of more than 9 fenner drives pdf user manuals, service manuals, operating guides , user manuals, operating guides & specifications

6 foot piece installation instructions Perfectly suited for aa, bb, and cc drives Reduced inventory… any belt, any time! No matter what equipment you are operating, productivity is critical.

With higher coefficient of friction, t.

The document is a design manual for fenner belt drive, detailing various types of belts and pulleys used in power transmission The manual provides comprehensive information on dimensions, designations, and performance characteristics of the products.