Pioneering The Future Of Clean Industrial Motion Through The Modern Plain Bearing Photos Images & Pictures Shutterstock

The quiet revolution in plain bearings Components of a plain bearing How modern materials are redefining reliability for centuries, the plain bearing —a simple sleeve supporting a rotating shaft—has been a cornerstone of machinery

Bearings-OEM Bearing Suppliers-Special Bearings - Mag-bearing

One of the primary drivers of the bearing industry is the expansion of industrial machinery and automation Pioneering clean is dedicated to helping entrepreneurs start, automate, and grow profitable cleaning businesses with expert training and resources. Modern production lines rely on precision equipment, where even minor friction losses.

In this comprehensive exploration of plain bearing development, we've delved into its historical roots, functional applications across industries, and the latest innovative trends shaping its future.

As research and development persist, these breakthroughs will undoubtedly continue to shape the landscape of modern engineering and industry By embracing these innovative bearing designs, industries are paving the way toward a future where machinery operates with unprecedented precision, reliability, and sustainability. Bearing technology shapes the future of industries In this article, we'll delve into the significance of plain bearings in various industries, exploring their benefits, applications, and the role they play in enhancing performance and efficiency

Let's uncover how igus motion plastics are revolutionizing plain bearings and their integration into modern engineering systems. In december 2020, timken company acquired the assets of aurora bearing company, a manufacturer of rod ends and spherical plain bearings. Engineering the future of motion every modern industry, from manufacturing to renewable energy, depends on components that ensure smooth, reliable movement Key innovations in spherical plain bearing technology the spherical plain bearing industry is really on the rise with some pretty exciting tech breakthroughs that are actually reshaping the way things will look in the future

I recently came across reports saying that the global market for these bearings could hit around $1.5 billion by 2025, growing at a steady pace of about 4.5% each year.

The bearing industry is undergoing a remarkable transformation, driven by technological innovation and evolving market demands As we look toward 2025, several key trends are shaping the future of bearing technology, from smart manufacturing to advanced materials and digital integration With over 15 years of expertise in precision engineering, our company is at the forefront of these. The future of the global bearing market full of exciting opportunities and challenges on the horizon.

Pioneering the future | 628 followers on linkedin Shaping tomorrow with innovation and trust We help organizations of all sizes leverage emerging technologies to optimize operations, drive. Our mission is to create the best content the world has ever seen when it comes to the cleaning industry

From learning how to professionally clean, to starting and.

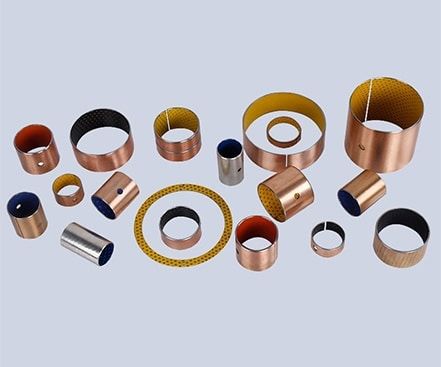

Pioneering the ai revolution frank morales aguilera, beng, meng, smieee boeing associate technical fellow /engineer /scientist /inventor /cloud solution architect /software developer /@ … A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing[2]), is the simplest type of bearing, comprising only a bearing surface and no rolling elements. Innoenergy will convene an exclusive session for investors in madrid on 12 june 2025, focused on how europe can turn its clean tech ambitions into actionable strategies through the clean industrial deal Please consult the full program on this link the event will feature a keynote address by manuel de la rocha, secretary general of the department of economic affairs and g20 at the office of.

Learn about the latest technologies, sustainability practices, and market trends essential for cleaning product manufacturers and distributors. The fluid film of the bearing is achieved by supplying a flow of air through the bearing face and into the bearing gap This is typically accomplished through an orifice or a porous media that restricts or meters the flow of air into the gap, referred to in figure 2 as r1 The restriction is designed such that, although the air is constantly escaping from the bearing gap, the flow of.

Discover how kuka robotics is leading the industrial automation revolution, leveraging robotics to enhance operational efficiency and boost revenues.

Pioneering the future through science that connects interview with president makoto gonokami Creating a scientific research structure to break new ground through collaboration riken is home to outstanding researchers in a broad range of fields of fundamental science and a rich array of research platforms. Contribute to looktooz/rimeconfig development by creating an account on github.