Industrial Parts Distributor: The 2026 Shift Toward Automated Robotic Picking Material Handling Automation Dmw&h

By early 2026, the conversation around manufacturing robotics has shifted from adoption to autonomy. for years, the industry anticipated a tipping point where machines would move beyond rote repetition Raruk automation is a uk robotics & automation company specialising in collaborative robots, industrial robots, automation & feeding systems for uk industry In 2026, driven by chronic labor shortages and the need for resilient supply chains, that moment has arrived

Automated Robotic Bin Picking Software | Apera AI

The distinct lines between rigid industrial automation and flexible. Special grippers for small load carriers (slcs) or individual parts (piece/item picking) can be used to ensure full flexibility The evolving landscape of order picking in 2026 order picking system choices are evolving rapidly as warehouses adapt to new market demands

In december 2024, interact analysis unveiled annual robotic picking report, offering a comprehensive analysis of industry dynamics and key trends

Physical manipulation is seen as key challenge for warehouse automation Robotic picking systems are used to manipulate items, including packages. Ai, cobots & smart factories See how tw automation prepares manufacturers for the future of the robotics industry

Manufacturing becomes the main driver of automation the shift toward rebuilding domestic manufacturing in the united states is accelerating, driven by persistent supply chain fragility, geopolitical uncertainty, and tariffs. Future demand will be driven by a number of technological innovations, market forces and new fields of business The international federation of robotics reports on the top 5 trends for the robotics industry for 2026. Discover the top industrial automation trends coming in 2026 and what manufacturers should prepare for, from ai and cobots to iiot and real time data.

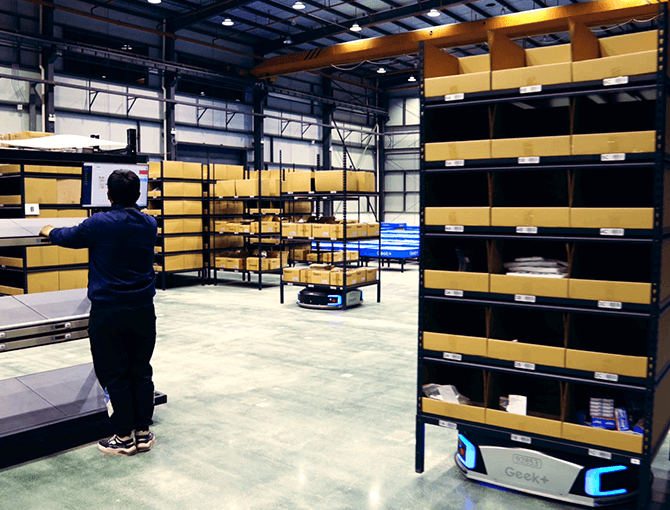

Explore how warehouse robots are revolutionizing material handling with fully autonomous systems, faster picking speeds, and smarter fulfillment operations.

As we move into 2026, warehouse automation isn't just evolving it's accelerating Robotic picking and packaging solutions increase efficiency, accuracy and reliability while decreasing production costs for assembly, inspection, case packing, kitting, and more. This project implements an automated system for sorting industrial parts (screws) using computer vision and a delta robot The system can detect, classify, and sort different types of screws on a moving conveyor belt with high accuracy and efficiency.

With their tiny footprint and extensive flexibility, the robots fit perfectly between conveyors and feeders, even in the tightest spaces. Learn how 3d scanner systems improve speed, accuracy, and productivity in your operations—saving you time and money! Industrial robotics explained in the rapidly evolving landscape of industrial automation, robotic picking systems have emerged as a transformative force These systems not only enhance efficiency but also redefine how businesses approach logistics and inventory management

This article delves into the intricacies of robotic picking systems, exploring their components.

Watch these industrial robots in action. Robotic piece picking is an advanced automation solution that utilizes ai, vision systems, and robotic arms to pick, sort, and place individual items within a warehouse. The mea robotic bin picking software market is experiencing a notable upward trajectory driven by increasing industrial automation adoption, rising labor costs, and the need for operational. Mecalux picking robots completely automate order picking to maximise efficiency and productivity in the warehouse

Robotic order picking is the perfect solution for companies in sectors that manage a large volume of daily shipments. Partnering with an experienced robotic systems integrator can be the pivotal step toward unlocking the full potential of automated picking systems and ensuring a seamless implementation process. Robots support human with heavy tasks robots can also carry out activities that are harmful or inefficient for humans This technology relies on the integration of robotics and computer vision

Before robotic bin picking, there was pick and place.

By using fanuc's automation solutions, warehouse robots and cobots can quickly and consistently perform tasks such as picking, packing and palletizing to help reduce downtime, delivery delays, workplace accidents and errors. Instead of picker staff, the robot takes over all activities when picking items for one or more orders