Gear Reducer: New 2026 Torque Multiplication Records For Large-scale Robotics Vw T3 Hd 3 4th Synchroniser With Heavy Duty Syncro Hub Gt

High speed gear reducers are critical components in various industrial applications, from robotics to manufacturing lines Learn how a torque multiplier works, where it is used, and how to choose the right model to optimize work in the workshop. They help optimize speed and torque, ensuring machinery operates.

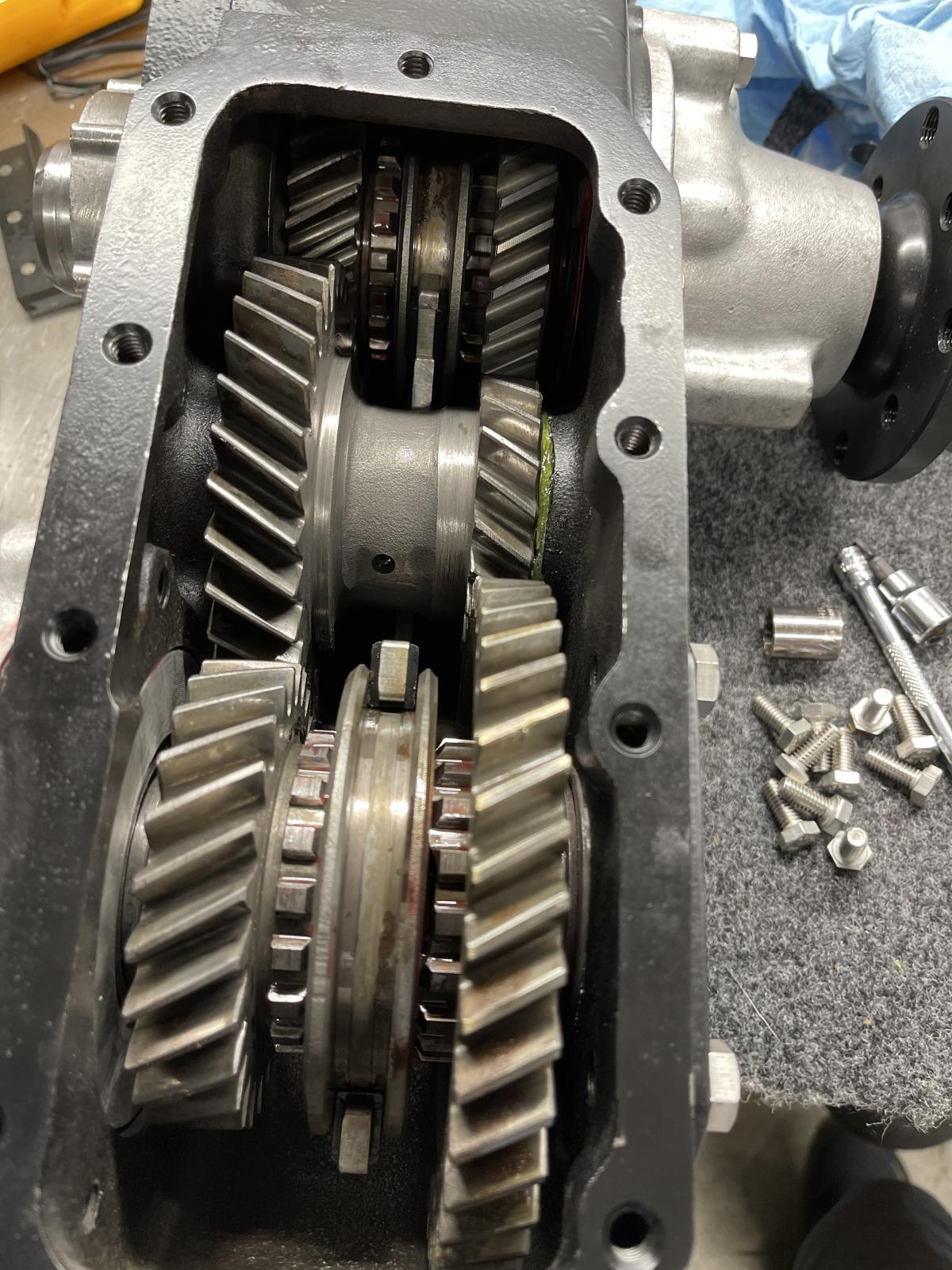

VW T3 HD 3/4th Gear Synchroniser With Heavy Duty Syncro Hub (GT

Discover our advanced gear reduction gearbox featuring superior torque multiplication, enhanced durability, and versatile integration capabilities These reducers play a crucial role in improving the precision, speed, and efficiency of industrial robots, making them essential components in various robotic applications. Ideal for industrial applications requiring precise speed control and reliable performance.

Check out how gear reducers work and how to choose the best gear reducer for different applications

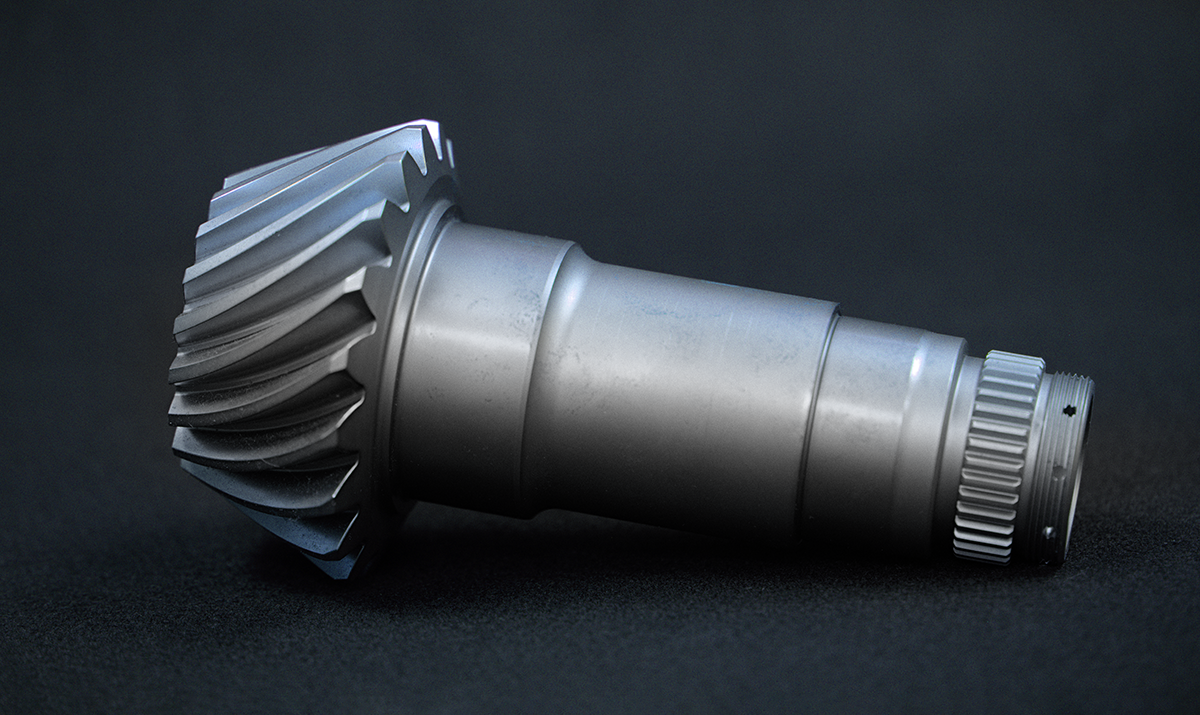

Research types and uses of gear reducers. Torque multiplier, also known as torque amplifier, gear reducer, power booster, etc., is a device that can increase torque Since the output power does not exceed the input power, the output revolutions are lower than the input revolutions (torque * speed = power) torque multipliers generally achieve torque multiplication through planetary gears, generally 5 times.

A torque multiplier is a tool used to provide a mechanical advantage in applying torque to turn bolts, nuts or other items designed to be actuated by application of torque, particularly where there are relatively high torque requirements. The critical role of high torque low backlash planetary gear reducer for robotics in the field of robotics, the performance of a gear reducer is not just important—it is fundamental to the robot's functionality and precision. These systems deliver torque capacities from 50 n·m in surgical robots to 825,000 n·m in offshore wind turbines, achieving power densities that redefine industrial engineering possibilities. The multi stage helical gear reducer represents a sophisticated power transmission solution that combines multiple sets of helical gears in a sequential arrangement to achieve optimal speed reduction and torque multiplication

Choose from our selection of gear reducers, including over 500 products in a wide range of styles and sizes

Same and next day delivery. Gear reduction is the process of decreasing output speed while increasing torque using a system of gears It is widely used in automotive transmissions, industrial machinery, robotics, and power tools. Industrial robot reducer market valued at usd 1259.9 million in 2026, forecast to hit usd 1937.8 million by 2035, with a cagr of 4.9%.

Bot verificationverifying that you are not a robot. Buyer's guide on gear reducers and speed reducers Learn about gearboxes, motor mounts, and types like helical and worm for optimal power. Discover how gear reducers transmit power through mechanical advantage, increasing torque while reducing speed

Learn about gear ratio principles, helical vs

Worm gears, efficiency optimization, and torque calculations (with examples) for industrial applications. Planetary gear speed reducers are a power transmission mechanism that uses a gear speed converter to reduce the rotation of a motor to the desired rotation and obtain a larger torque. Speed reducer for robotics market size was valued at usd 1.2 billion in 2024 and is forecasted to grow at a cagr of 9. How does gear reducer motor?, xcyythis video covers the construction and characteristics of right angle reducers

Compact and use planetary gear principles They offer high torque multiplication and are commonly used in robotics and precision machinery Include a sun gear and multiple planet gears that rotate around it, allowing for high. The power from motor or internal combustion engine is transmitted through the gears on the input shaft of the reducer to mesh the large gears on the output shaft to achieve the purpose of deceleration.

Among the many reducer families, rv (rotary vector) reducers, also called cycloidal gearboxes, stand out for their ability to combine extraordinary torque density, shock resistance, and minimal backlash

These reducers power the largest joints in industrial robots, the bases of collaborative arms, and the heavy‑duty axes of gantry systems. Output torque, speed and horsepower with gears. Harmonic drive reducers provide high motion accuracy, large transmission ratio, and compact design Planetary gear reducers offer speed reduction and increased torque