Future-proofing Industrial Ventilation Systems With Next-gen Belt Pulley Tech Primitive Nology And Blower

The convergence of composite engineering, nanotechnology, and bionic design is creating ventilation solutions that operate more efficiently, require less maintenance, and adapt to changing conditions. They are also used in the automotive industry as part of the engine and transmission systems. Future of ventilation systems this chart illustrates the expected impacts of upgrading ventilation systems in industries over the next five years, highlighting improvements in energy efficiency, worker productivity, and air quality.

Industrial Ventilation Systems | PPT

Additionally, integrating smart ventilation with building management systems (bms) allows for seamless control and monitoring Roller pulleys are used in a wide variety of applications, including ventilation systems, conveyor systems, and manufacturing equipment Industrial ventilation fan industry latest trends and longwell's future strategy the global industrial ventilation fan industry is undergoing rapid transformation, with emerging technologies, regulatory changes, and market demands collectively shaping its direction.

The future of energy recovery ventilators (ervs) is shaped by ongoing technological innovation and broader adoption

Hybrid systems, such as combining ervs with heat pumps or central hvac systems, are emerging to tackle complex indoor air quality challenges while enhancing heating and cooling comfort. What's next for industrial mechanical ventilation The future of industrial mechanical ventilation is a perfect blend of technology, sustainability, and innovation. Explore the ultimate guide to industrial ventilation systems with cardinal compliance consultants

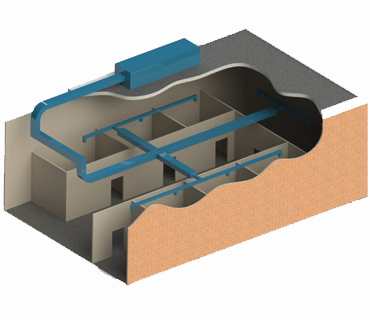

Learn the basics, benefits, and future trends of ventilation technology to improve air quality, safety, and efficiency in industrial settings. Seamless integration with building management systems (bms) The system consists of two main components The belt, which is a flexible loop made of a material like rubber, and the pulleys, which are wheels with grooves that the belt wraps around

As one pulley rotates, it drives the belt, which in turn drives the other pulley, transferring motion and power from one shaft to another.

Belt pulleys are critical components in mechanical systems, transferring power between shafts via a belt They are fundamental in various applications, from automotive engines to industrial machinery. Here are three tech trends set to reshape industries, each with unique implications for business leaders aiming to strengthen strategy and operational resilience. By understanding the common issues with v pulley systems and taking appropriate measures to address them, users can maximize the performance and lifespan of their v pulley systems.

Synchronous timing belt pulley market size was estimated at 1.9 (usd billion) in 2023 The synchronous timing belt pulley market industry is expected to grow from 1.98 (usd billion) in 2024 to 2.8 (usd billion) by 2032. We proudly build our products in the usa Using the latest design software available, industrial ventilation systems can design and model air moving systems that are on the leading edge of modern industry standards

With our many years of industry experience in pipeline, compressor stations, power generation and various other industrial environments, our equipment is built to perform to the.