Flexible Shaft Coupling: The 2026 Solution For Complex Robotic Misalignment Industrial Hardware 33701 High Precision

Learn how flexible couplings enhance machinery efficiency and longevity by mitigating shaft misalignment and reducing wear This flexibility reduces the load on bearings and absorbs shocks and vibrations from the machinery. Discover their benefits and applications in various industries.

Industrial Hardware 118425 High-Misalignment Precision Flexible Shaft

Flexible couplings are designed to accommodate misalignment between shafts Among various types, flexible shaft couplings are commonly used to absorb vibrations by allowing for shaft misalignment They can absorb shock, reduce vibration, and compensate for minor deviations in shaft alignment.

Flexible shaft couplings transmit torque between two shafts while accommodating misalignment, absorbing shocks, and protecting against torque overload, much like a circuit breaker

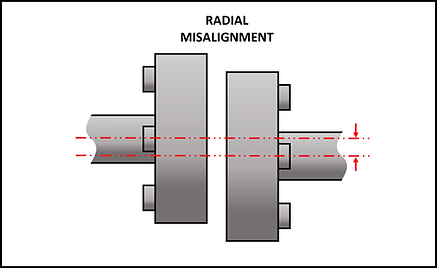

The types of misalignments are angular misalignment, lateral misalignment, and axial misalignment. Flexible shafts, being torsionally compliant slender long shafts, offer a combination of remote and series elastic actuation over an obstacle Flexible shaft couplings are mechanical devices designed to connect two shafts together while compensating for slight misalignments, reducing stress on machinery Flexible insert couplings are mechanical devices that feature metal hubs and a flexible polyurethane shaft coupling insert

This style of coupling connects two inflexible rotating shafts and transmits power from one shaft to the other while accommodating any misalignment. In the field of mechanical engineering, flexible coupling shaft misalignment is a critical issue that can lead to various problems in rotating machinery Misalignment occurs when the rotational axes of the connected shafts do not align perfectly. Choose from our selection of misalignment couplings, including precision flexible shaft couplings, flexible shaft couplings, and more

Same and next day delivery.

Sdp/si offers a wide range of flexible couplings designed to compensate for shaft misalignment and handle various load conditions, making them ideal for use in automation, robotics, instrumentation, and light industrial applications. Discover flexible shaft couplings, expertly designed to connect machinery shafts for efficient torque transmission and precise alignment, enhancing performance. Shaft couplings, beam couplings, and helical couplings, are all types of flexible couplings that allow for axial motion misalignment. Misalignment shaft couplings absorb misalignment between two rotating shafts and can be used in high power and high torque applications including motors, gearboxes, and other precision drive components.

It is always necessary to take into account the size, geometry, or operating temperature of a given machine How much vibration and efficiency loss will result from the misalignment of shaft centers depends on shaft speed and coupling type Acceptable alignment tolerances are thus a function of shaft speed and coupling geometry. Examine the roles and functions of shaft couplings

Browse various types of shaft couplings including driveshafts, motor couplings, and flexible shaft couplings.

Discover how shaft couplings transmit torque, handle misalignment, and protect machinery This simple guide covers coupling types, alignment tips, and maintenance best practices. Discover the top 3 shaft coupling types—rigid, flexible, and universal joints Learn how to install each like a pro to boost torque, reduce vibration, and cut downtime.

Flexible shaft couplings flexible shaft couplings transmit torque between two shafts while accommodating misalignment, absorbing shocks, and protecting against torque overload, much like a circuit breaker Discover the different types of shaft couplings, why they fail, and how to choose the right one for your machinery Get expert tips to avoid costly breakdowns. Flexible couplings allow transmission of rotational force between two shafts with a slight tolerance for misalignment.

Nbk flexible shaft couplings, specifically the mjt flexible coupling disk type, provide reliable torque transmission by accommodating misalignment in angular, axial, and eccentricity dimensions.

Shaft coupling for robotics introduction to shaft coupling shaft coupling is an essential component in the field of robotics, connecting two shafts to transmit power and motion Understanding its complexity and applications can enhance the efficiency of robotic systems Types of shaft couplings shaft couplings come in various types, each designed for specific applications and performance. Unlike flexible couplings, rigid couplings do not allow for any misalignment between connected shafts

This characteristic makes them ideal for applications requiring exact alignment and high torque transmission. Angular misalignment is the difference in the slope of one shaft of the machine relative to the slope of the other shaft of the machine As with radial misalignment, angular misalignment can occur in the horizontal or vertical direction (or a combination of both). To avoid premature coupling failure it is critically important in design selection to match the correct coupling to the misalignment condition or combination of conditions present

Shaft misalignment may be angular, parallel or axial, with further complications when any combination of these occurs (complex misalignment)

Flexible couplings are typically designed to compensate for specific.