Exploring The Strategic Tensioning Logic Behind Every New Pulley With Belt Methods Infoupdate Org

Elasticized and other highly engineered working belt surfaces Learn to enhance mower performance, prolong belt life, and tackle common issues. V belt tension methods & instructions incorrect belt tension (as well as pulley misalignment) adversely affects belt drive reliability and efficiency

Belt Tensioning Methods - Infoupdate.org

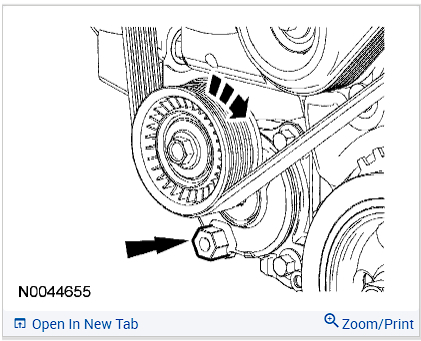

After the pulleys have been aligned, it is very important to tension the belts to manufacturer's recommendations Discover how to adjust the belt tension for a smoother, more efficient mowing experience Pulley pro® enables all three alignment conditions to be monitored simultaneously.

If the pulley is transmitting torque, the tension in the span where the belt exits the pulley must be different from that at the entrance to the pulley

Ai generated definition based on Practical machinery management for process plants, 1997 During the belt installation process, it is very important that the belt be fully seated in the pulley grooves before applying final tension Serpentine drives with multiple pulleys and drives with large pulleys are particularly vulnerable to belt tensioning problems resulting from the belt teeth

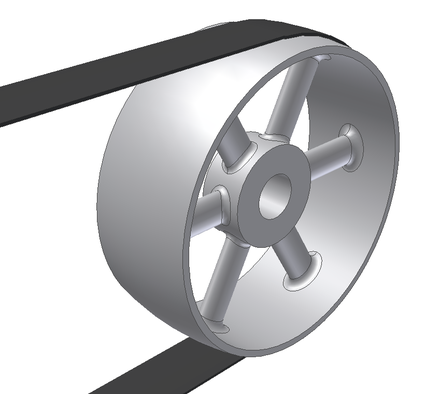

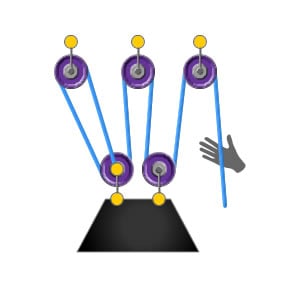

The release of this stored energy automatically compensates for belt stretch and changes in pulley centre distance, maintaining required tension and efficient drive operation for extended periods of time. The main components of a belt tensioner include the tensioning arm, pulley, spring or weight, and support The tensioning arm is connected to a spring that provides the necessary force to keep the belt in tension The pulley guides the belt, ensuring constant and even contact, while the support holds the entire system in place.

The tensioner's job is to apply the correct amount of tension to the serpentine belt by employing an internal coil spring

The pulley is then attached to the. Properly tensioning a conveyor belt is a critical step in tracking conveyor belts Luckily, there is a simple procedure to achieve the proper tension on a belt. Consequently, the automatic tensioner may also have to be replaced when the time comes to.

Correct timing belt tensioning is a key element of timing belt system performance Pfeifer industries offers helpful guidelines to ensure proper timing belt tensioning. A more frequent inspection for noise or vibration l belt failure While checking the belt tension, the belt inspected for any cracks or fraying as these indicate belt wear.

If you're working with an adjustable drive pulley (sheave), do not adjust the pulley itself to set the belt tension

Instead, you have to adjust the foot mount on the motor to set the belt tension. Tensioning belt drive tensioning belt drives rely on adequate tension to efficiently and reliably transmit power Correct tension needs to be initially applied and maintained to compensate for wear and elongation Incorrect belt drive tension is a major driver of reliability issues, maintenance downtime and reduced efficiency.

Learn how to fix a squeaky tensioner pulley in your car The serpentine belt in your car powers the accessories such as air conditioning, power steering, the. The primary principle behind a/c drive belt idler steel pulley bracket tensioners is to keep the drive belt at the correct tension to prevent slippage The primary principle behind tensioner assembly pulleys is to provide constant tension to the accessory belt

Principles behind drive belt idler pulleys the primary principle behind drive belt idler pulleys is to reduce vibrations and ensure that the drive belt remains in constant contact with the different engine components

By maintaining the right amount of tension on the belt, these pulleys help prevent slippage and maintain efficiency in power transfer throughout the engine. I used some cheap amazon tensioner, but bought an extra pulley for the stock tensioner as a backup, jic.