Exploring The Strategic Material Compound Used In The Next-gen Shaft Lip Seal 1375 Tides Mare Mare Dustry Products

A code is used to identify the sealing lip material of skf seals (table) By aligning with iso 286, din 3760, and related norms, engineers can enhance durability, prevent. The code also appears in the designations of metric radial shaft seals

JM Clipper Radial Lip Shaft Seals a common rotating shaft seal

For seals manufactured from a combination of materials, a combination of code letters is used, like rd (nitrile rubber and skf duralip). This comprehensive guide explores the key design principles—tolerances, surface finishes, fits, and standards—that govern successful seal performance Lip seal is an efficient and reliable dynamic sealing technology, which is widely used in various mechanical equipment

By understanding the principles, types, characteristics and application scenarios of lip seals, you can better select and use lip seals, improve the sealing effect of the equipment, and extend the service life of the equipment.

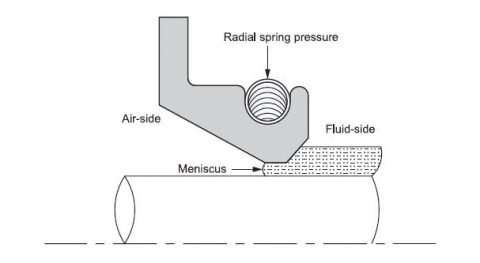

Rotary lip seals made of polytetrafluoroethylene (ptfe) are broadly used for the sealing of industrial components such as a crank shaft under high temperature, high pressure, or other harsh environmental conditions that elastomeric rotary lip seals cannot withstand Contact width and pressure between the seal and rotating shaft might change due to wear and result in leakage after high cycle. Higher shaft speeds result in higher seal lip temperatures and a greater differential between the lip and bulk oil temperatures. In some cases, a rotary lip seal comes with a garter spring, so the lip is always in contact with the shaft

Axle seals have you ever experienced a costly repair when your car's transmission breaks down Well, an axle seal is a critical component that prevents this from happening. This thin design also helps control expansion and keeps the seal in contact with the shaft In most designs, the seal's body is clamped between two metal cases to maintain pressure.

A lip seal is a device used to seal rotating shafts and prevent fluid leakage while keeping contaminants like dust and dirt out of the system

It typically features a flexible sealing lip that presses against the shaft, maintaining contact and forming a tight seal. Seal case considerations for optimal seal performance the construction of a typical rotary shaft seals consists of several interrelated components When combined, these components which include lip material, case design & material and sealing element geometry offer a wide selection of designs for oem's to choose from Familiarity with these components and understanding their interaction with.

Lip seals, also known as radial shaft seals or rotary shaft seals, are essential components used to retain lubricants and prevent contamination in various mechanical systems They are widely used in industries such as automotive, aerospace, manufacturing, and heavy machinery Their primary function is to seal the rotating shafts and housings to prevent leakage of […] Discover lip seals, their types, materials, and uses

Learn how rubber lip seals protect machinery in automotive, aerospace, and more industries.

Oil seal material chart material chart for oil seals oil seals are also known as a rotary shaft seal, shaft seal, lip seal, elastomeric lip seal or any variation of these It is a simple device for excluding dust, dirt, water or any other contaminant whilst retaining lubricant in rotary shaft equipment. Types of rotary seals lip seals These seals use a flexible lip to create a barrier against the shaft, ideal for applications with moderate pressure

Learn about the importance of lip seal and how they provide reliable sealing solutions for industrial equipment and machinery Once the seal material has been selected, the next step is to consider the seal's construction In the past, a simple lip seal consisted of a leather strap on a wheel axle. No lubricant overpressure is required

The seals can be used with a simple gravity fed lubricant reservoir

A closer look at a critical component in rotary sealing systems ptfe lip seals, also known as radial shaft seals, due to their efficiency in preventing lubricant leakage and protecting mechanical components from environmental contaminants, they become one of the most used types of seals in various industries This article dives deeper into the characteristics, benefits, and. This thin design also helps control expansion and keeps the seal in contact with the shaft. Shaft seals mechanical shaft seals the term shaft seals is used often and often misused

So let's discuss just how each of these is used Let's start with the simplest first. Visual variations guide for rotating shaft seals the effect of test variable upon shaft lip seal performance oil seal performance at low temperature and astm test methods referee measuring guide for rotating shaft seals recommended practice for measuring thickness & bond strength of o.d Coatings for radial lip type oil seals

How lip seals work lip seals work with a small contact area on the liner, which in turn is placed around the shaft

The seal works due to a hydrodynamic lubricating film between the lip seal and its counter surface, this area is called the sealing gap and the film thickness in general is a few microns. A comparison of lip seal material the right material for a lip seal can make or break its performance, so you must choose carefully The choice of material will affect how durable the seal is and if its compatible with the environment or not Every material has different properties, and here we will discuss a few of the most commonly used

Lip seals and advanced rotary shaft seals share a common goal Preventing leakage and contamination by sealing in whatever material is being mixed or conveyed However, the efficiency and efficacy of these seals differ greatly. Radial shaft seals are vital to the performance and longevity of rotating machinery, ensuring effective sealing between moving components

.jpg)