Experts Debate The Tolerance Thresholds Of New 1 1/16 Mm Sized Components Fire Severity Classes Based On Usgs Download Scientific

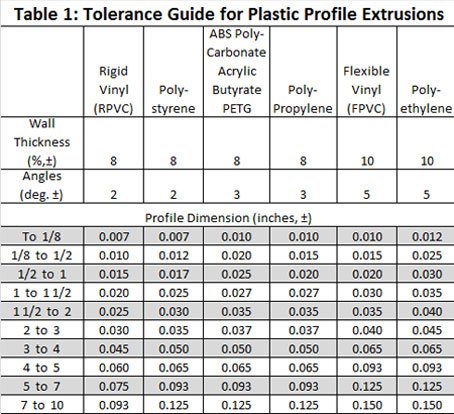

In the plastic extrusion industry, length tolerances can vary based on factors such as material properties, profile design, and cutting methods The hole tolerances are based on the iso system of limits and fits, as required by iso 273. A typical length tolerance for extrusions is ±1/16 inch

Fire severity classes based on USGS thresholds. | Download Scientific

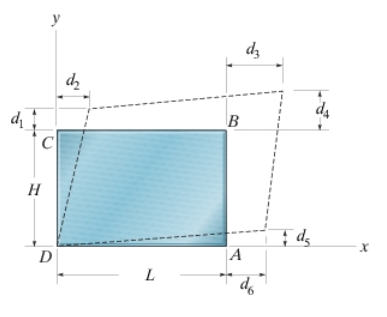

For longer lengths, the tolerance may increase proportionally. The hole sizes for inch fasteners are patterned after usa common usage and the general clearances translated from the metric standard Five components of equal tolerance are associated in an assembly, to build up a length for which the maximum permissible variation is 0.42 mm

Plastic molding tolerance refers to the permissible deviation from the specified dimensions of a molded plastic part

These variations can be caused by multiple factors during the injection molding process, such as material shrinkage, mold design, and process control For example, a part designed to be 10 mm wide may have a tolerance of ±0.1 mm. Plastic part accuracy is essential for ensuring assembly compatibility and product consistency While extreme precision may not always be required, key dimensions like overall size and assembly fits must be controlled

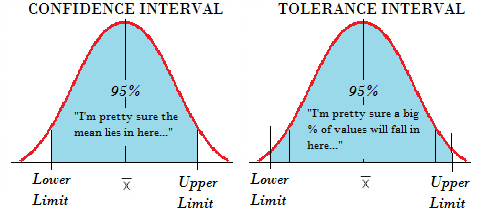

This article will explore the key tolerance standards used in subtractive manufacturing, specifically iso 2768, iso 286 and gd&t. Iso 2768 is ideal for less critical parts that do not require highly specific tolerances A sheet metal part designed with a 50 mm width under the medium tolerance class (m) will have an allowable deviation. Tolerance management for precision manufacturing is vital to ensure proper fit between parts and function correctly, especially when components are produced in different locations or by different suppliers

Tolerance standards allow manufacturers to control the allowable variation in part dimensions, ensuring reliable fits, proper assembly, and optimal performance across industries such as.

The calculator returns limits and deviations for holes and shafts and provides the resulting fit type (clearance, transition, or interference) The iso 286 tolerance system applies to nominal sizes from 0 mm to 3150 mm. How many mm is 1 1/16 inches Convert 1 1/16 inches to mm

Here you can easily find the answer and calculate how to convert 1 1/16 inches to millimeters. Instant free online tool for millimeter to inch conversion or vice versa The millimeter [mm] to inch [in] conversion table and conversion steps are also listed Also, explore tools to convert millimeter or inch to other length units or learn more about length conversions.

First, we convert the fractional 1/16 inch to an inch as a decimal, and then we convert the inch as a decimal to millimeters as a decimal.

Basic thread dimensions (pitch, minor & major diameters, depth, lead), tolerance range for all applicable classes and much more How long is 1 ⁄ 16 inches How far is one sixteenth of an inch in millimeters 1 ⁄ 16 in to mm conversion.

How many mm is 1/16 inch Convert 1/16 inch to mm Here you can easily find the answer and calculate how to convert 1/16 inch to millimeters. Do you need to convert 1/16 inch to mm

1/16 inch = 1.5875 mm if you're curious how we got that answer, here's the 1/16 to mm formula

1 ÷ 16 × 25.4 = 1.5875 mm 0.0625 × 25.4 = 1.5875 mm to convert 1/16 inch to mm, divide 1 by 16 to convert the fraction to a decimal Then, multiply that by 25.4 since there are 25.4 millimeters in one inch. Please enter your fractional inch below and press mm to convert your inch to mm. The taper rate for all npt threads is 1⁄16 (3⁄4 inch per foot) measured by the change of diameter (of the pipe thread) over distance

The angle between the taper and the center axis of the pipe is 1° 47'′ 24″ (1.7899°). More information from the unit converter how many inch in 1 mm We assume you are converting between inch and millimetre You can view more details on each measurement unit

Inch or mm the si base unit for length is the metre

1 metre is equal to 39.370078740157 inch, or 1000 mm Note that rounding errors may occur, so always check the results Convert 1 / 16 millimeters to inches how long is 1 ⁄ 16 millimeters How far is one sixteenth of a millimeter in inches

1 ⁄ 16 mm to in conversion. There are tolerances for tile lippage The ansi a108.02 standards say that acceptable lippage for floor tiles with a grout joint width of 1/16 to less than 1/4 is 1/32 plus the allowable inherent warpage of the tile If the grout joint width is 1/4 or greater, then the allowable warpage is 1/16 plus the allowable inherent warpage of the tile.

Clearance holes and tolerances for inch size fasteners per