Ensuring Future Industrial Safety Through Robust Bearing Flange Engineering Cap Jps Rollers Com

Through detailed stress analysis, engineers can optimize the design, select appropriate materials, and implement reinforcement strategies to enhance the bearing's ability to withstand high loads and operating conditions, ultimately ensuring robust performance and longevity in demanding industrial environments. You can prevent costly failures, leaks, and downtime by following best practices in alignment, bolt tightening, and routine inspections. The flange keeps the bearing in place and helps align the shaft properly

flange bearing safety cap | JPS Rollers.com

This makes them perfect for equipment like conveyors, robots, and car parts, ensuring smooth and reliable operation. Proper installation and maintenance of steel flanges are essential for ensuring safety, efficiency, and durability in piping systems Flanges play a pivotal role in piping engineering, connecting pipes, valves, and other equipment to create a secure and efficient pipeline system

Understanding the types of flanges available and the key factors to consider when selecting and using them is essential for ensuring the integrity and reliability of industrial piping systems

In this comprehensive guide, we delve into the world of. While flanges may appear simple, their role in pressure containment and gasket sealing integrity makes them vital to the safety of plant personnel and the environment. Introduction in industries where reliability, ease of installation, and robust performance are paramount, flange mount bearings emerge as a cornerstone of mechanical design Covers design analysis, manufacturing processes, and industry applications.

Flange engineering now addresses environmental stewardship Lifecycle analysis shows that optimized flange designs reduce carbon footprint by 18% through material minimization and extended service intervals. Flange mounted bearings play a role in all sorts of mechanical systems, providing support and reducing friction for rotating shafts In this comprehensive guide, we will discuss the purpose, types, installation, and maintain of flange mounted bearings to help you understand their critical role in ensuring smooth and efficient operations.

This article provides a comprehensive guide to flange ball bearings, explaining their design, functionality, applications, and benefits

For anyone involved in procurement, engineering, or manufacturing, understanding the nuances of flange bearings is crucial for selecting the right components for optimized machinery performance and longevity This article is worth reading because it offers. Bolted flange joint is subjected to many uncertainties such as material and geometric nonlinearities, load distribution and its relaxation Hence, there is a need to understand the behaviour of bolted flange joint under different conditions, with varying bolt load, internal fluid pressure, temperature and occasional loads.

In the late 19th century, with the development of precision machining techniques and metallurgical advancements, flange bearings evolved into more specialized components capable of meeting stringent industrial requirements Maintaining flange bearings properly is crucial for ensuring their longevity and optimal performance in various industrial applications According to a report by the american society of mechanical engineers, improper maintenance can lead to a 30% reduction in bearing life, resulting in costly downtimes and repairs. Here is a guide to flanges

Definition, working principle, types, uses, and application case analysis in different industries.

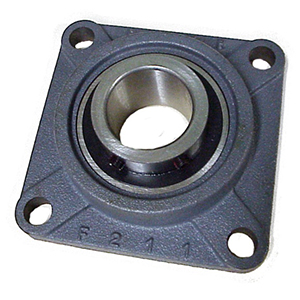

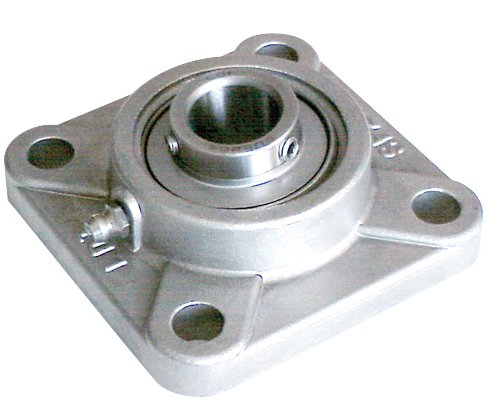

These bearings, mounted directly onto a flange block, offer a robust and adaptable means of integrating bearing assemblies into various mechanical systems A flange block mounted bearing is essentially a bearing unit that combines a rolling bearing with a housing, typically made of cast iron or steel, which includes a flange for mounting purposes. Learn how to create systems that withstand failures and perform consistently under various conditions with our guide on design for robustness and reliability. Adjustable flange bearings are a versatile and reliable solution for precision engineering applications

Their adjustable mounting, robust construction, and precision engineering make them an excellent choice for supporting radial and axial loads in various industrial settings. In automotive engineering, flange couplings connect drivetrain components such as the engine and transmission to the driveshaft, ensuring smooth power delivery and enhancing overall vehicle performance. Flange usage boosts efficiency and safety in varied applications, underscoring their importance in piping realms Knowing face types and material is essential across many industrial applications

As an example, stainless steel flanges guarantee extended usability and durability, particularly in petrochemical projects.

Proper installation of asme flanges is crucial to ensuring the integrity, safety, and efficiency of piping systems in various industries Flange bearings are a critical component in a wide range of mechanical systems, from industrial machinery to automotive applications These specialized bearings play a crucial role in supporting and guiding rotational motion, reducing friction, and ensuring the overall efficiency and reliability of the equipment they are integrated into. Designed for the critical demands of food and beverage sectors

The bearing units combine precision engineering with robust material choice. Our first objective in this work is to provide a synthesis of, and a roadmap to current ml use in reliability engineering and safety applications Our second objective is to outline some future opportunities for ml in reliability and safety applications. Developing economies, in particular, face difficulties in balancing industrial growth with the enforcement of robust hse standards, resulting in inconsistencies in workplace safety and environmental policies (omotayo et al, 2024).