Ensuring Future Automotive Handling Stability Through The Optimized Rod End Bearing Btf Wholesaler From Mumbai

Needle bearings, rod end bearings, and spherical bearings play a crucial role in automotive manufacturing, motorsports, and aftermarket upgrades, ensuring smooth drivetrain operation, precise steering, and durable suspension performance 5 optimized vehicle handling stability by considering suspension roll center height, equivalent steering stiffness, and roll steering coefficient as optimization objectives, improving the vehicle's handling stability through optimization of suspension hardpoint coordinates and bushing stiffness. Whether you're optimizing a race car, upgrading your vehicle,

Rod End Bearing - BTF Rod Ends Wholesaler from Mumbai

The importance of rod ends is their ability to facilitate precise motion control and load transfer while maintaining alignment and reducing mechanical stress within the system. Explore the intricacies of automotive suspension systems, their components, functions, and how they enhance vehicle stability, comfort, and handling. Enhance your car's performance with our ultimate guide to rod end linkage

Discover precision rod ends, ball joints, and more for every application.

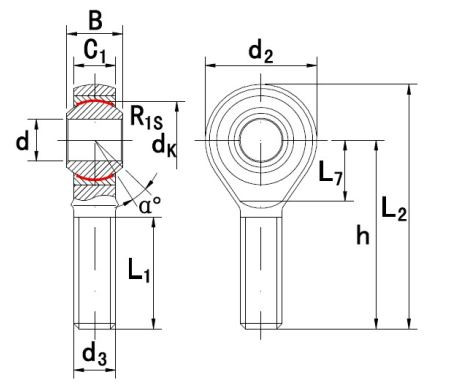

Discover the complete guide to rod end bearings (heim joints) including applications, size chart, benefits, and why bywb bearing is your reliable supplier. Rod end bearings, also known as heim joints or rose joints, are essential mechanical components used in various applications to provide rotational and oscillating movement between two linked components They play a crucial role in transferring motion and load in different industrial and automotive systems, offering high precision and efficiency in challenging environments. For example, in an automotive steering system, worn rod ends can lead to imprecise steering, posing safety risks

How to choose the right rod end bearing selecting the correct rod end bearing is crucial for ensuring the optimal performance and durability of the system Here are key factors to consider: Bent rod ends cannot be unbent, and any time a rod end bends you should replace it immediately and rectify the issue which caused it to bend Similarly, any time a spherical bearing or rod end develops slop it is best practice to replace it and rectify the cause.

Common applications the adaptability of rod ends means they feature in a broad spectrum of industries

In suspension and steering linkages, offering precise control and movement Critical for aircraft control systems—ensuring reliability and safety under extreme stresses. Rod ends used in automotive industry are the utmost important elements that play a critical role in suspension system and steering devices They are exposed to high sudden forces in both axial and radial directions and so the life performance is one of the big challenge for the manufacturers

In this study, the effect of design parameters on increasing the fatigue life of rod ends was. Yes, rod ends with bearings can be customized in terms of size, thread type, and bearing material to meet the specific needs of different applications, ensuring optimal performance and compatibility with other components. Discover the ultimate guide to rod end bearings Shop online for a wide selection of spherical rod ends, ball joints, and more to meet all your needs.

Explore our comprehensive guide on tie rod ends for bywb bearing

The bearing allows for angular misalignment, accommodating variations in orientation between connected components Rod ends find extensive applications in various mechanical systems, such as automotive steering linkages, control arms, and aircraft control surfaces. Enhance equipment performance and durability with expert insights. We're on a journey to advance and democratize artificial intelligence through open source and open science.

A rod end bearing is a common type of mechanical joint used on the ends of control rods The steering columns in most cars, trucks and other vehicles, for example, feature tie rods with a rod end bearing. Explore vehicle dynamics and handling in automotive engineering, uncovering key forces, innovations, and future trends that enhance driving performance and safety. Found in chassis parts like ball joints and tie rods and critical to the steering and handling of a vehicle, bearings reduce friction and ensure smooth rotation.

The united states automotive hub bearing market is characterized by steady growth, driven by increasing vehicle production, technological innovations, and a shift towards electric and hybrid vehicles.

Compression system and cell format selection depend on clamping force distribution, heat management, and structural integration, ensuring reliable, durable, and safe battery operation across evs, hybrid vehicles, and stationary energy storage systems Why are tie rods leading the compression system segment in battery modules?