Engineers Dispute The Tolerance Levels Of Traditional 1 5/8 To Mm Conversions Average Component Questions In

Iso 286 table hole tolerances calculator international tolerance grades variations on dimensions without tolerance values are according to iso 2768 The hole tolerances are based on the iso system of limits and fits, as required by iso 273. All tolerance limits are given in mm

Manchinists Levels – L.V Level Co.,Ltd

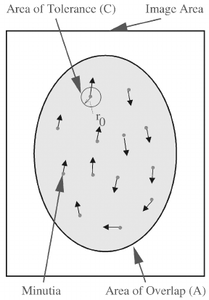

Iso 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. The hole sizes for inch fasteners are patterned after usa common usage and the general clearances translated from the metric standard Engineering tolerance defines the allowable variation in dimensions that ensures parts achieve proper fit, performance, and interchangeability

Automotive components often require tolerances as tight as ±0.0007 inches, while smartphone parts demand fits within ±0.005 mm, demonstrating the essential role of precision for both reliability and appearance

Standards such as iso 2768 guide. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. This is just one example for linear tolerances for a 100 mm value Engineering tolerance is the permissible limit or limits of variation in

This article will explore the key tolerance standards used in subtractive manufacturing, specifically iso 2768, iso 286 and gd&t. Typical tolerances of manufacturing processes in the past, one of the traditional weaknesses with graduating mechanical design engineers is their inability to select tolerances Most students were reasonably proficient using one or more cad packages and could produce drawings which were pretty good (given their limited experience levels) However, despite knowing how to put a tolerance on a.

Overview of tolerance standards tolerance standards provide guidelines on the acceptable amount of dimensional variation in parts, covering aspects such as form, fit, and function

Understanding how to apply tolerances ensures that parts are produced to the desired quality and can be assembled seamlessly in mass production In manufacturing, tolerances are necessary because no process is. Tables of permissible deviations for external and internal sizes, distances, external radii, chamfer heights and broken edges in tolerance classes f, m, c and v. For conversions to metric and inches, the utmost most important conversion to remember is 25.4 mm per inch

From there you convert your mm to whatever metric unit and your inches to whatever imperial unit. During the rolling process the rollers bow slightly, which results in the sheet metal being thinner on the edges The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer's standard gauge, which has no inherent tolerances. Convert between metric and sae (inch) wrench sizes with this comprehensive comparison chart

Find the closest equivalent sizes for your tools, whether working with us standard (sae) or metric fasteners.

Explore the significance of tolerance levels in precision manufacturing and how they impact product quality, safety, and reliability across industries Gain insights from hartford technologies to excel in precision engineering. Surface roughness conversion chart tables manufacturing knowledge menu surface roughness review the following charts and tables convert surface finish or roughness between selected industry standard units Please enable javascript to view the page content

Always ensure to use the exact spanner size for the corresponding nut size, as a loose fit can lead to rounding off the corners of the nut This guide is generally applicable but always refer to specific standards or manufacturer recommendations if available. Jason explains how to tell at a glance whether a drawing has inch or metric dimensions in this question line video. Clearance hole chart for inch bolts and screws

Drill size and hole diameter for normal, close and loose fit classes are tabulated.

Asme b1.1 inch size un external screw threads formulas and calculator per Asme b1.1 ansi/ asme external screw thread size chart All units are in inches Wrench openings table for hex and square nuts per

Learn ansi, din (iso) & mil Standards for precision machine dowel pins in carbon or stainless steel Size, material hardness & press fit hole tolerance. 0.01mm/m 1 2 3 4

Clearance holes and tolerances for inch size fasteners per