Efficiency Data: Why Tb Woods Is Redefining Torque Control In Pumping Stations 12e Sert Gstore

Variable frequency drives are powerful tools that can greatly enhance the efficiency and control of pumping operations Elements discussed include various sump designs and discharge arrangements, station type and layout requirements, and environmental and power requirements. Discover the advanced capabilities of torque control in darwin motion vfds by cm industry supply automation

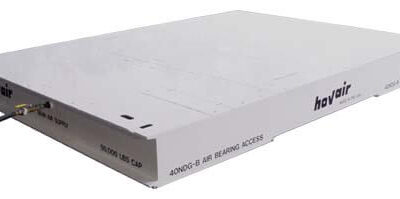

Heavy Duty Transporters: Redefining Capacity and Control - Hovair Systems

Learn how this precision operating mode optimizes industrial processes for enhanced efficiency and performance reliability. This manual provides information and criteria pertinent to the design and layout of civil works flood control pumping stations Torque control is a crucial feature in modern variable frequency drives (vfds), also known as frequency inverters

It allows for precise control of motor torque, making it ideal for specific industrial applications like winding and unwinding materials.

A variable frequency drive is an electronic device used to control the speed and torque of an electric motor by varying the frequency and voltage of the power supplied to the motor This capability allows vfds to adjust the motor speed to match the demand of the system, which is particularly beneficial in pumping applications. Enhance the efficiency and durability of your power transmission systems with tb wood's couplings Whether you require torque transmission, vibration dampening, misalignment compensation, or customized solutions, tb wood's couplings deliver unparalleled performance.

Now available up to 10hp! The wf2 provides high performance sensorless vector operation which allows 150% torque down to 0.5hz The wf2 also sports a wide variety of enclosure options ranging from chassis/ip21 to nema 12/ip55. One of the most important tools that installers have to ensure correct mounting of power transmission components is the torque wrench

And, yet, this tool is used far too rarely in these installations.

The current price schedule for electric power from the supplying utility or the market price of engine fuel can be used to determine the costs for all stations except for large stations For large stations, a study of future energy costs over the life of the project is justified. Pumping stations are crucial components in water management systems, playing a pivotal role in transporting water and wastewater from one location to another. The location of the pumping station will be a function of its size

But even medium to small pump stations need access by maintenance crews and equipment, and ease of access should always be considered In all cases, the pumping stations should be protected from physical damage by a local waterway, using one hundred (100) year flood. Pumping stations in a water distribution system are necessary where water is pumped directly into the system (e.g From a lake) or where pressure has to be increased because there is an insufficient difference in water levels in gravity flow distribution systems

There are two general types of pumps

Vertical turbine pumps and centrifugal pumps Capital costs are high, but the most expensive. Explore innovative design and construction of pumping stations by civil engineers with integrated data analytics. Tb wood's is an industry leading designer and manufacturer of mechanical power transmission equipment for industrial control

Our mechanical product lines include Clutch and brake, synchronous and belted variable speed drives Grid, disc, jaw, gear coupling and elastomeric coupling products We would like to show you a description here but the site won't allow us.

Their purpose is to improve the operation efficiency of pumping stations, where ls is in fact a control means to achieve efficiency improvement

Pumps are consuming a considerable part of the power supply. Crude oil pumping station for reasons of efficiency, economy, and safety, the preferred method of moving large quantities of petroleum or petroleum products on land is by dedicated, large diameter, buried, transmission pipeline Due to the friction loss created by liquids moving through the piping the pipelines experience pressure losses over the length of the piping Later industrial gas turbines were introduced

Stock sheaves have capacities ranging from 1/2 to 108 Models offered in four types for use in a variety of tough applications including aggregate and oilfields.