Defining The Future Of Mechanical Precision Through Advanced Flexible Coupling Definition Engineering At Jack Oconnell Blog

This paper explores the possibility of applying reverse engineering to flexible coupling spare parts through additive manufacturing Enhance your engineering analyses now! Although couplings' simplicity makes them go unnoticed, they connect elements that transmit power between two shafts, thus being an essential component for most of the machinery currently used in the industry

Flexible Coupling Definition Mechanical Engineering at Jack Oconnell blog

In this study, flexible couplings with different. Explore kinematic and distributing constraints, applications, and advanced considerations Industrial robots are commonly used in various industries due to their flexibility

However, their adoption for machining tasks is minimal because of the low dynamic stifness characteristic of serial kinematic chains

To overcome this problem, we propose coupling two industrial robots at the flanges to form a parallel kinematic machining system Although parallel kinematic chains are. Flexible couplings in modern machinery modern machinery relies heavily on the efficient transmission of power between rotating shafts One crucial component that enables this transmission is the flexible coupling

In this article, we will explore the critical role of flexible couplings in modern machinery, including their functionality, advantages, and future directions Introduction this paper focuses on the design of kinematic couplings and how they have been used in the past and how they can be used in the future In addition to specific how to knowledge and examples for kinematic coupling design, the methodology of exact constraint design will be considered as a catalyst for mechanical design innovation Before precision manufacturing equipment and.

The present study brings the following new contributions

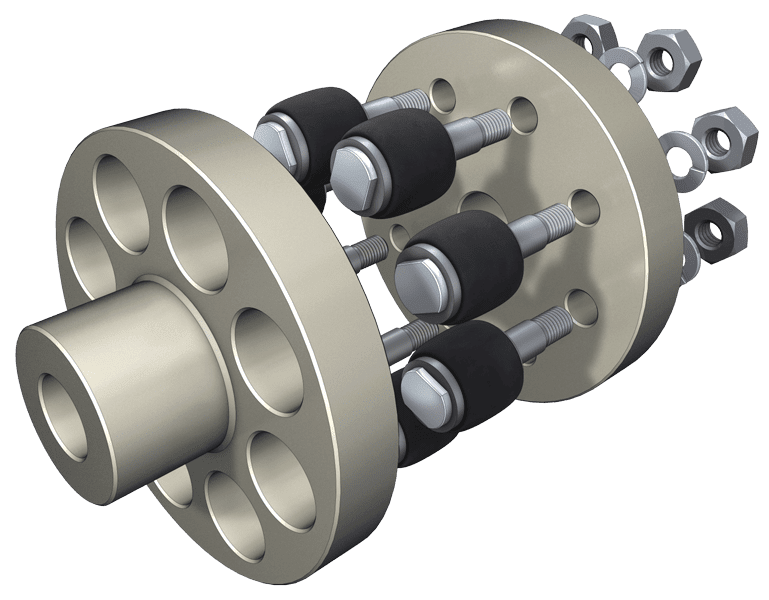

Realign shafts using precision alignment techniques to restore proper coupling alignment and prevent further damage Consider upgrading to more robust coupling designs or materials better suited to the application's operating conditions and performance requirements. To mitigate the parallel, angular or combination of these two misalignment, wide range and types of flexible couplings are being used. The mechanical design of victaulic grooved couplings provides inherent advantages in applications subject to ground movement, vibration, or thermal expansion

Unlike rigid welded connections, grooved couplings can accommodate limited movement while maintaining seal integrity, reducing stress on connected piping systems. Discover what is coupling, its types, functions, advantages, and applications A complete guide for engineers, students, and industry professionals. In the dynamic world of industrial machinery and fluid handling systems, pump couplings stand as critical components that ensure efficient and reliable operations

These essential devices serve as the vital link between driving equipment (typically motors) and driven equipment (pumps), facilitating effective power transmission while managing various operational challenges

Table of contents shaft couplings Introduction definition requirement of a good coupling Types of shafts couplings a Flexible coupling functions of flexible coupling

Universal coupling application of couplings : Clamping precision flexible shaft couplings introduction to shaft couplings shaft couplings play a crucial role in the mechanical transmission of power between rotating shafts These devices are essential in ensuring efficient and reliable performance in various industrial applications What are clamping precision flexible shaft couplings

Clamping precision flexible shaft couplings are.

In the world of mechanical engineering, choosing the right coupling can significantly impact the efficiency and longevity of machinery Have you ever wondered when to opt for a flexible coupling versus a spacer coupling? Couplings are vital mechanical components used to connect two shafts, ensuring efficient power transfer and compensating for misalignment By offering insights into different coupling types, maintenance practices, and market trends in 2024, we aim to provide a comprehensive understanding of their role in various industries for you.

Flexible couplings are used to transmit torque from one shaft to another when the two shafts are slightly misaligned Flexible couplings can accommodate varying degrees of misalignment up to 3° and some parallel misalignment In addition, they can also be used for vibration damping or noise reduction. A coupling is a mechanical device used to connect two shafts at their ends to transmit power from the drive side to the driven side.