Deep Dive Into The Strategic Torsional Rigidity Provided By Flex Coupling Jwcg Sus304 High Rigid Shaft Jinwang Hardware

Flexible couplings & universal joints 1.0 introduction couplings are divided into categories Specific details vary depending on the different types and their functions. As compared with flexible couplings, rigid couplings have limited application

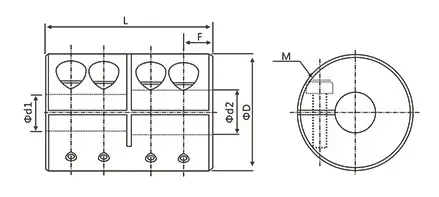

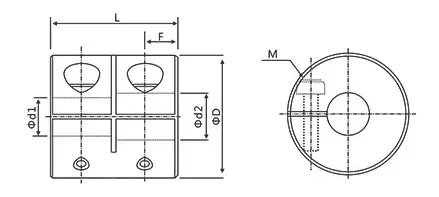

High Precision Steel Flex Disc Shaft Coupling For Pump Type TSK TLK T

Rigid couplings do not have the ability to compensate for shaft misalignments and are therefore used where shafts are already positioned in precise lateral and angular alignment All of these have bearing on coupling selection The flex coupling combines all the advantages which can be expected of an ideal flexible coupling

Flexible shaft coupling considerations flexible shaft couplings provide torque transmission while helping to improve machine performance and life, but using a low performance coupling or the wrong type of coupling can impede mechanical performance, reduce throughput, and even cause downtime

Products that are too rigid or used outside their recommended ratings can create excessive bearing. In this method, the torsional stiffness of each robotic joint is calculated considering the influence of the component stiffness and contact stiffness between components. 🔧 flex couplings may look simple, but they solve complex problems in power transmission—connecting rotating shafts, absorbing vibration, and managing misalignment across critical equipment From cnc machines to wind turbines, the right flex coupling can improve efficiency, protect machinery, and reduce downtime

In our latest article, we explore the different types of flex couplings, how. The torsionally resilient, flexible coupling is responsible for effectively dampening the shocks and vibrations that occur in drive systems during operation Due to the special spring and damping properties of the profiled coupling sleeves, elco effectively limits torsional vibrations. The d coupling's modular design enables very flexible integration into a wide variety of engine test rigs

We adapt the length of the coupling, connections, and torsional rigidity to your test rig.

Coupling manufacturers routinely supply weight, inertia, center of gravity, and torsional stiffness data for use by the system analyst During the development of a new disc coupling product line, discrepancies were noted between historically and widely used coupling torsional stiffness data vs The stiffness measured in laboratory tests. Torsional stiffness torsional stiffness is a key mechanical property of flexible couplings, expressed as the torque required to deform the coupling by a unit angle

This property affects the coupling's ability to handle torque without excessive deformation, which is important for maintaining system stability and performance Lovejoy offers a wide range of torsional couplings engineered to solve torsional vibration problems found in diesel engine driven equipment and other applications where torsional vibrations are prevalent These include all internal combustion engines, reciprocating pumps and compressors, as well as variable frequency drives (vfd) Lovejoy torsional coupling are designed to dampen torsional.

Various factors, including torque, misalignment, speed, operating environment, and maintenance requirements, will dictate the appropriate coupling type

Let's dive deeper into these factors: Any misalignment can lead to increased wear and potential damage to the coupling and connected equipment Generally, spacer couplings have a limited torque transmitting capacity compared to some flexible coupling types This repository provides a deep dive into hexagonal architecture within a spring boot project

The documentation contrasts layered architecture, showcasing its traditional structure and highlighting its drawbacks, such as performance overhead, scalability challenges, and tight coupling between layers Backlash is eliminated by the press fit of the elastomer into the hubs Through variation of the shore hardness of the elastomer insert, the coupling system can be optimized for the ideal torsional characteristics.features Misumi flexible shaft couplings, ultra high torque disc, clamping, for servo motor, feature an aluminum body, enabling high torque transmission with remarkable torsional rigidity.

Provided to youtube by cdbabyimma flex · deep divealpha grind℗ 2024 deep divereleased on

Flex executive offers business growth consulting and fractional leadership for entrepreneurs and teams Built for extreme torque, misalignment and vibration in demanding industrial drives. The overlaps allow the beams to perform in parallel, thereby increasing torque. This page introduces diaphragm coupling

Eagle industry is a comprehensive manufacturer of mechanical seals and equipment products Our technologies and products are used in the automotive, marine, rocket/aircraft, and various industries around the world. Torsional rigidity is defined as how much an object of specified material resists twisting force, also known as torque It is based on both the […]

This article will dive into the key differences between grid and gear couplings, comparing their torque transmission capabilities, misalignment tolerance, and vibration control.

Solid rigid shaft to shaft couplings design equations and calculator The a shaft to shaft solid coupling does not allow for misalignment, except axial, but enables the extension from one piece of equipment to another. Several factors should always be taken into consideration when looking to specify flexible couplings These are torsional stiffness, backlash, torque, life, and attachment system