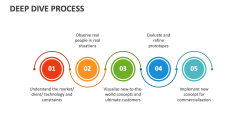

Deep Dive Into The Strategic Heat-treatment Processes Used At Us Tsubaki A How Amassed 1 5bn Lbs Of Cheese Th Currently

Tsubaki roller chains are highly durable. Part of the tsubaki series, a cult favorite and perennial bestseller in japan, this treatment utilizes advanced technology to penetrate deep into the hair, deliv Imagine transforming raw metal into a masterpiece of durability and strength with just a few carefully controlled steps

Amazon's Strategic Growth: A Deep Dive into Its Q1 2024 Performance

This is the essence of heat treatment—a crucial process in metallurgy that can dramatically enhance the properties of metals Tsubaki premium moist hair treatment is a luxurious hair mask that deeply nourishes and hydrates dry, damaged hair, restoring its natural moisture and luster In this comprehensive guide, we delve into the intricate stages of heat treatment, from heating to soaking and cooling, explaining each phase's.

Making small changes to the time and temperature can make metal much stronger without making it heavier

This controlled process makes aluminum alloys stronger and lighter, which makes them great for purposes where both are necessary The normalizing heat treatment process serves several key objectives that make it a versatile and widely used procedure It is highly effective in refining the coarse, uneven grain structures resulting from prior manufacturing processes like forging, casting, or hot rolling. Learn about the t6 heat treatment process, detailed mechanical properties, common applications, and how to source certified material.

Tsubaki power transmission, llc holyoke roller chain manufacturing facility has been the backbone of american industrial power transmission The global heat treatment services market is booming, projected to reach \\$137 billion by 2033 with a 4.2% cagr Discover key trends, segments (aerospace, automotive, etc.), leading companies, and regional insights in this comprehensive market analysis. The heat treatment process is used to improve the grain structure of the material

In steel treatment specifically, heat treatment converts austenite crystal into martensite.

The practice of heat treatment of metals, a pivotal process in the realm of metalworking, has evolved significantly from its rudimentary origins Centuries ago, blacksmiths discovered that heating and rapidly cooling metals like iron and steel could dramatically alter their properties, leading to stronger, more durable materials. A heat treatment operator is responsible for overseeing the transformation of raw metals into finished products This role requires meticulous attention to detail and a deep understanding of material science

Operators must adhere to established heat treatment recipes that dictate temperature profiles, cooling rates, and exposure times tailored to each material type We would like to show you a description here but the site won't allow us. Therefore, heat treatment occupies a very important position in machinery manufacturing Heat treatment of aluminum alloy aluminium alloy heat treatment technology is a technology to change the structural organization of aluminium alloy by controlling the heating rate, holding time and cooling rate.

Tired of frizz and damage

Tsubaki's wide range of power transmission and motion control products are here for your various operational needs From the simplest to the most complicated applications, we have the right product for you. Compare our product options below to find the right solution for your specific needs. Learn how us tsubaki elevated its quality management program to new heights after implementing enterprise quality management software

Learn about heat treatment basics, key processes, and techniques used to enhance metal and alloy properties for different applications. Engineered for quality and performance ds performance into every energy series chain We start with the highest quality steel, manufacture all parts to stringent tolerances, and provide the most efective heat treatment processes to maximiz rated working load and shock load resistance Heat treatment is a controlled process that involves the heating and cooling of materials to alter their physical and mechanical properties

It is commonly used to modify the microstructure of metals and alloys, resulting in improved hardness, ductility, toughness, and other desirable characteristics.

The document provides an overview of various heat treatment processes used in metals, aiming to alter mechanical properties for improved serviceability Key processes discussed include annealing, normalizing, quenching, case hardening, and tempering, each with specific purposes and outcomes The techniques enhance characteristics such as strength, wear resistance, and ductility while. Heat treating transforms metals for optimal performance

Learn the essential heat treatment processes and their applications and benefits in manufacturing.