Decoding The Strategic Torque Transfer Principles In Every V Belt Drive Pulley Metro Cast Iron Number Of Grooes 1 To 20 At ₹ 170

Our application technology experts offer you free support service regarding the application of our products and also help solve your drive problems By altering the direction of force or creating mechanical advantage, pulleys optimize energy transfer in systems such as engines, conveyors, and hvac equipment. Especially regarding large volumes you should make use.

V Belt Pulley factory, Buy good quality V Belt Pulley Products from China

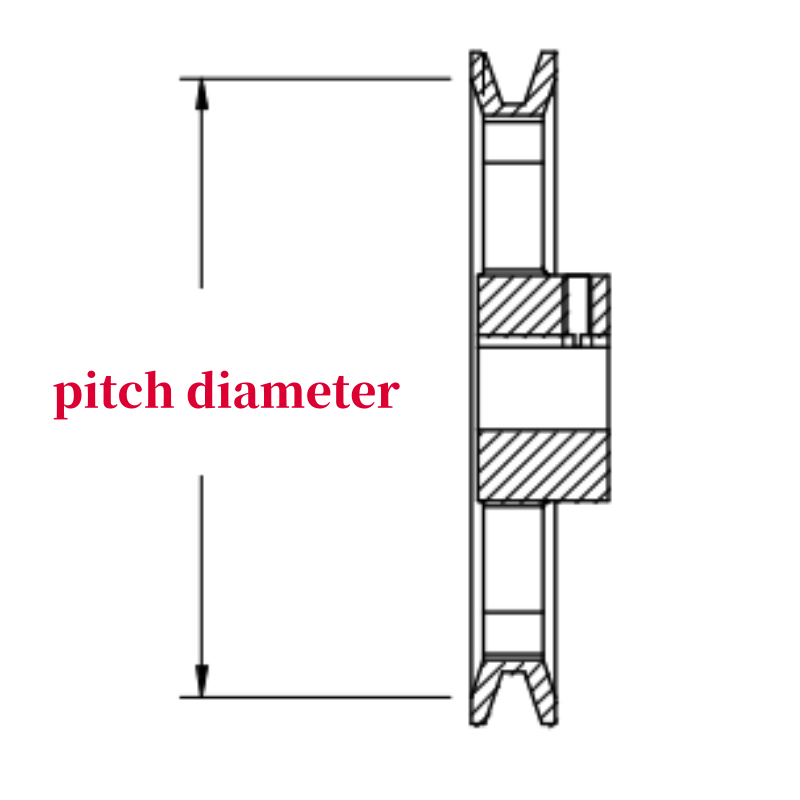

The v shape of the belt tracks in a mating groove in the pulley (or sheave), with the result that the belt cannot slip off Regardless of whether we look at the. Calculate belts power transmission and efficiency the torque available at the driven wheel or pulley (a) can be expressed as

Kinematics in belt and gear driven systems belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft.

Discover essential horsepower and torque rating formulas for timing belt pulleys, gears, and flanges Optimize your synchronous drive system with accurate torque load and horsepower calculations. For toothbelt drives, preload maintains the correct contact pattern between the belt teeth and sprocket grooves Any belt will stretch when a load is.

To determine the required motor drive torque for a belt and pulley system, calculate the torque required acceleration, constant velocity, and deceleration. A flat belt pulley interacts with one surface of the belt A v shaped pulley allows the belt to wedge tightly in the groove, increasing friction and torque transmission. Same and next day delivery.

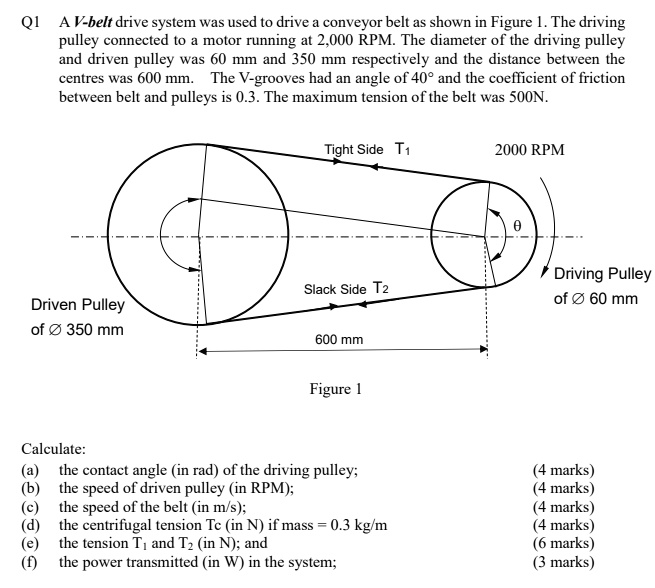

Introduction in belt drives, power is transmitted between at least two pulleys by a belt

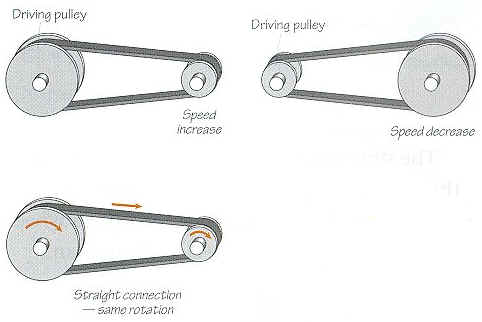

One pulley drives the belt (driving pulley) and the other pulley is driven by the belt (driven pulley) In belt drives, the speed is often reduced, so that in these cases the smaller of the two pulleys is the driving pulley Operating principle of a belt drive power transmission with belt drives. Enter the total axial force, the radius of the drive pulley, and the efficiency of the system into the calculator to determine the pulley torque.

How it works, its components, design, advantages, disadvantages and applications. Maximum transmittable circumferential force in the article basics of power transmission it was shown with the belt friction equation that the maximum frictional force f f,max between belt and pulley at a given tight side force f t or slack side force f s can be determined with the formulae listed below. The pulley torque calculator is an essential tool designed to determine the torque required by a pulley system to move or lift a load efficiently This calculation is crucial in various engineering fields, especially in mechanical design and material handling.

Friction surfaces, through which the torque can be transmitted from the drive pulley to the driven pulley

Belt drives are described along with different types, working procedures, selection, advantages, disadvantages, power transmission, etc. The system consists of two main components The belt, which is a flexible loop made of a material like rubber, and the pulleys, which are wheels with grooves that the belt wraps around As one pulley rotates, it drives the belt, which in turn drives the other pulley, transferring motion and power from one shaft to another.

Belt drive torque calculation this calculator determines the torque transmitted to the output shaft of a belt drive system The torque transmitted by a belt drive system is inversely proportional to the pulley diameters This means that a smaller pulley diameter will result in a higher torque, and vice versa. This article provides helpful information about the different torque requirements in a typical motor drive for a belt and pulley transmission system

It also contains formulas for estimating the torque required for a body mass's constant velocity, acceleration and deceleration.

Discover how to optimize belt drives for maximum efficiency and performance in this comprehensive guide. Understand the relationship between the torque in a sprocket or pulley and the tension that exists in a chain or belt