Decoding The Strategic Surface Treatment Technology Applied To Koyo Bearings Vs Ntn Durability Comparison In Food

Here, you will find product information and case studies relating to bearings and oil seals In this report, the progress and future prospect of rolling bearing technology is described, focusing on the birth and evolution of tapered roller bearings which has played a major role in the development of the automobile industry, taking examples of life improvement technology by material and heat treatment and friction reduction technology. You can also download technical calculation tools, cad drawings and various catalogs to help you with the bearing selection process.

KOYO Bearings vs. NTN Bearings: Durability Comparison in the Food

Conclusion the technology behind koyo bearings represents the perfect blend of innovation, precision, and quality The surface treatment of slewing bearings involves processing the surfaces of their components to enhance performance and extend lifespan, which can improve the wear resistance, corrosion resistance, and fatigue strength of slewing bearings. The surface integrity of bearing steel materials largely determines the life of mechanical parts like bearings and gears

Optimizing the process parameters or applying surface modification technology can improve the surface integrity of materials

In this paper, the definitions and characteristics of the evaluation parameters of surface integrity and their influences on mechanical part. Along with a legacy in traditional industrial applications, koyo remains a leader in advancing innovative new materials, manufacturing expertise and precision engineering capabilities ranging from extremely large bearings with outer diameters as large as seven meters to miniature bearings as small as one millimeter providing unique customer. The application of material surface strengthening technology can not only solve the difference between the structure and requirements of the surface and the core, but also make the surface further obtain some special working performance to meet the working surface of koyo bearings working under specific conditions To enhance the durability of the bearings, koyo applies surface treatments such as heat treatment and coating

Bearing heat treatment is a critical manufacturing process that significantly enhances the mechanical properties and service life of bearings The primary goal of bearing heat treatment is to achieve optimal hardness, wear resistance, and fatigue strength while maintaining adequate toughness for demanding industrial applications. In order to develop bearings that meet these requirements, great advances will first have to be made in such areas as basic theory and analysis Metallic materials and heat treatment

New materials (resins and ceramics)

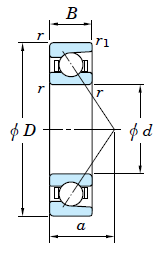

This process occurs in a vacuum chamber where a solid coating material is converted to vapor through physical means (typically sputtering or evaporation) and then condenses as a thin film on the bearing surface. Search for koyo distributors across the united states. Supplier of industrial products including bearings, seals, power transmission, lubricants, hydraulics, and more, servicing all of australia. The second digit of a bearing number indicates the bearing series which denotes the toughness / strength of the bearing

Bearing strength is the maximum stress load that the unit can bear or hold before the structure fails It can be measured by tensile strength, tensile elongation, compressive strength, flexural strength, modulus and. Koyo bearings in quality, price, durability & applications Sh bearings 1) by using the heat treatment technology developed by jtekt to perform special heat treatment on high carbon chromium bearing steel, we have improved the surface hardness of these products and provided them with compressive residual stress, which has led to high reliability especially in terms of resistance to foreign matter.

Jtekt is confident that you will find this new catalog useful in the selection and use of rolling bearings.

Jtekt offers a vast range of bearings for the automotive industry including various types of tapered roller bearings, needle roller bearings, thrust bearings, ball bearings, angular contact bearings, spherical roller bearings, cylindrical roller bearings, thrust roller bearings etc. Gotoh extending the service life of rolling bearing is one of effective methods to achieve improved reliability, weight reduction and downsizing This paper introduces new tapered roller bearings with improved surface property realized by a newly developed heat treatment process. If only central axial load is applied to the bearing, select such tolerance range class as to provide clearance in the radial direction for outer ring