Data Insights: Why Retaining Rings And Snap Rings Fail In High-vibration Zones Crescent External Rg Crescent External Rg Sae Products

Avoid costly retaining ring failures Din 471 retaining rings for shafts, also known as circlips or snap rings, are essential components in various mechanical assemblies, providing a reliable and secure method for axial retention of components on shafts. Explore common causes like improper installation or groove wear and how to fix them with help from huyett.

Retaining Rings & Snap Rings | Smalley

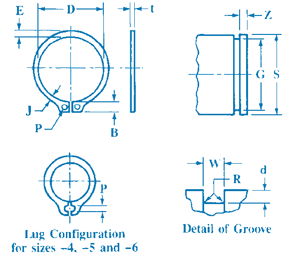

Retaining rings play a crucial role in securing components in demanding applications, such as power tools A portion of the retaining ring protrudes from the groove to create a shoulder to prevent components from migrating from their position during operation. Yet, the number one cause of failure is not the ring itself but groove deformation

In this article provided by smalley, you will understand why grooves fail and how to prevent those failures to avoid costly repairs, safety risks, and damage to your product's reputation

Retaining ring failure can lead to costly downtime and equipment damage, but what causes it In this guide, we explore the #1 reason retaining rings fail and reveal how a simple design adjustment can make all the difference. Most retaining ring failure issues can be traced back to a few common causes, many of which are preventable with proper design, installation, and maintenance To learn more, read our original post.

To enhance performance under such demanding circumstances, several key design and material modifications. Snap rings, sometimes referred to as retaining rings, are a prime example While they may appear simple, these circular fasteners are critical for keeping parts properly positioned, especially in equipment exposed to constant movement or vibration. Failure of a retaining snap ring application can result from failure of the ring itself, failure of the groove, or both

If a ring fails, the cause is likely to be from shearing of the ring

Shear failure occurs when a ring is installed in a groove and loaded by a retained part with both the groove and the retained part having a compressive yield strength greater than 45,000 psi (310 mpa) Master the structural differences between snap rings and retaining rings to optimize component selection, load bearing, and installation tools. By using distance and vibration measurements for snap ring verification, the manufacturer became accurately able to identify improperly seated snap rings that they had been missing through manual monitoring methods. About smalley retaining rings, snap rings, circlips (tapered section rings) and laminar seal rings

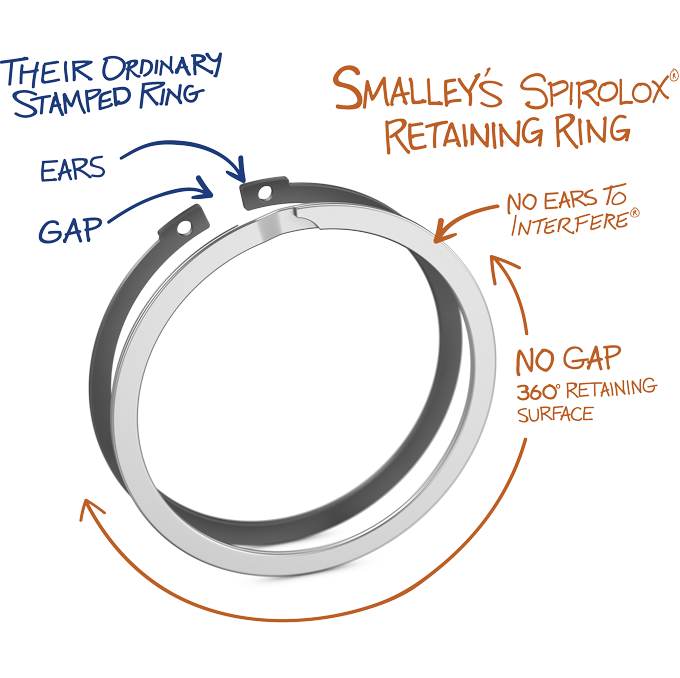

Advantages of a spirolox retaining ring Easiest, fastest option compared to a custom design over 6,000 standard sizes in stock to choose from better balanced compared to tapered section retaining ring tapered section retaining rings have lugs that contribute to imbalance and excess vibration during high speeds No yielding during installation or rotation Under extreme loads, this can lead to deflection of the ring and ultimately to failure

If a ring fails, the cause is likely to be from shearing of the ring.

A deformed snap ring can cause serious snap ring failure Discover the main factors that cause snap rings to deform and how to avoid them. Proper functioning of a retaining snap ring depends on the ring remaining seated on the groove bottom External rings cling to the groove bottom because the ring id is slightly smaller than the diameter at the bottom of the groove.

Find quality retaining rings from top, trusted brands at motion today Browse our full collection of retaining rings and other sealing and gasket accessories here. The function of retaining rings in the realm of mechanical engineering and industrial design, retaining rings play a pivotal role in ensuring the integrity and reliability of various machinery and equipment In this blog, we will delve into the functionality.

From installation to specifications to types and tools, our retaining ring guide covers everything

Learn how to choose the ideal retaining ring for any application! In industrial machinery, they are used to hold components in place under high stress and vibration conditions Aerospace applications rely on the lightweight and robust nature of retaining rings to maintain structural integrity without adding unnecessary weight Choosing quality with eastern seals

A snap ring or retainer ring is a fastener that holds a bearing in an application in place