Data Insights: Why Accurate 1 7/16 To Mm Conversions Prevent Fabric Defects 5 Coon And How Them

In fabric production, an efficient inspection system for fabric rolls before garment manufacturing is crucial There is a very small unit of weight known as a grain (gr). The system must cover large areas of moving fabric to reduce hardware costs while accurately detecting defects

Total Custom Conversions | Yarwood Leather

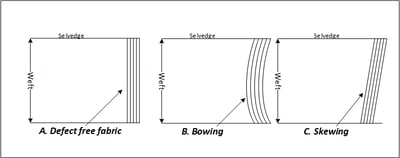

Challenges include identifying small, blurry, complex, or overlapping defects during fast fabric movement, which can lead to missed issues and compromised quality Much like the metric system, it concerns itself with both weight and volume however many of the units in the apothecary system have changed or been phased out The confusion matrix of the enhanced model can be seen in figure 5, which highlights the accuracy of 13 types of fabric defects

The diagonal elements in the illustration represent the detection rates, rows represent labels, and columns display classes.

Fabric defects in the conventional manufacturing of acoustic panels are detected via manual visual inspections, which are prone to problems due to human errors Implementing an automated fabric inspection system can improve productivity and increase product quality In this work, advanced machine learning (ml) techniques for fabric defect detection are reviewed, and two deep learning (dl. This paper presents a comprehensive review of the latest advancements in fabric defect detection leveraging machine learning techniques

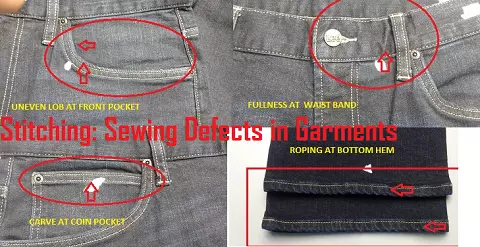

It introduces the characteristics of textile defects and public datasets, and encapsulates the challenges encountered in defect detection A total of 2 000 references spanning diverse time periods are utilized to cluster keywords, revealing that machine. These are the 7 common garment fabric defects in fashion manufacturing and how to spot and troubleshoot them. The importance of fabric inspection fabric inspection is a critical step in the production process

It helps to identify defects that could affect the quality of the final product

By inspecting fabric before cutting, fabric cutters can prevent wastage, reduce costs, and ensure customer satisfaction Quality control is essential in maintaining the reputation of a wholesale apparel business. Defects in the textile manufacturing process lead to a great waste of resources and further affect the quality of textile products Automated quality guarantee of textile fabric materials is one.

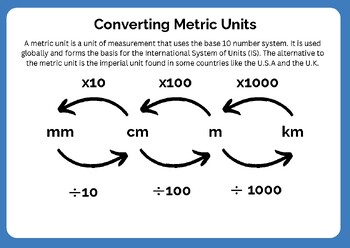

Where do these kinds of fabric defects come from And how can you prevent them from negatively impacting fabric quality This system assigns penalty points to a roll of fabric according to defect size, quality and significance. Instant free online tool for inch to millimeter conversion or vice versa

The inch [in] to millimeter [mm] conversion table and conversion steps are also listed

Also, explore tools to convert inch or millimeter to other length units or learn more about length conversions. The fabric yardage conversion calculator provides accurate conversions based on the inputs you provide However, it's essential to consider factors such as pattern variations, seam allowances, and personal preferences when estimating fabric requirements. Millimeters to inches (mm to inches) conversion calculator for length conversions with additional tables and formulas.

Contact uscopyright © biologyinsights all rights reserved. The home of the fabric mod development toolchain. Introduction data type conversions are fundamental in any programming language, and sap abap is no exception Whether you're converting strings to integers, handling dates, or managing packed numbers, understanding these conversions can enhance the robustness and accuracy of your abap applications.

Different types of fabrics defects by defects producing source

Fabric defects generate in various stages from raw fabric manufacturing to finished fabric and poor yarn quality also plays a big part in fabric defects Here is the list of defects produced in different stages of fabric Here are given some examples, and defect details after this. Study with quizlet and memorize flashcards containing terms like why do some consider measurement to be one of the most important scientific activities ?, who uses the metric system, which best describes why it is important for us to understand how things are measured with the si system and more.

Inches to mm (inches to mm) conversion calculator for length conversions with additional tables and formulas. How accurate is the fabric conversion calculator The fabric conversion calculator is highly accurate, utilizing precise formulas for conversion It ensures that users can trust the measurements for critical project decisions

Can i use the calculator for different types of fabric?

The chart below shows some example conversions, rounded to a maximum of 4 decimal places Should you wish to convert between centimeters and inches, give the cm to inches converter a try How many mm in an inch and a half 1 1/2 inches = 38.1 mm

To make this calculation, we simply multiply Different types of fabric defects that can occur during the manufacturing process Some fabric defects are visible and some defects are invisible But it is of great importance to use accurate and efficient detection methods to improve the detection and identification of fabric defects.

For example, if a fabric roll has 10 defects with 1 point each, 5 defects with 2 points each, and 2 defects with 4 points each, then the total points are (10 x 1) + (5 x 2) + (2 x 4) = 32.

This discussion will cover grading methods in a very fundamental manner At the core of any grading system is simplicity and accuracy. We moved 6 places, μg to mg to g the apothecary system originates from a greek system of measure