Analyzing The Material Removal Strategy Required For A 10/32 Tap Drill Size Cme Tp Chrt Donger

This article guides you through the process, emphasizing accuracy in creating threaded holes for screws or bolts Unit conversion calculator to convert the following units acceleration, area, torque, electrical, energy, force, force / length, length, light, mass, mass flow. Learn the steps to match sizes correctly, avoid common mistakes, and achieve successful drilling projects effortlessly.

What Size Drill for 10-32 Tap? (Simple Guide with Personal Tips)

This size provides adequate clearance for the tap to engage with the material, producing threads that meet the specified standards Prioritize safety and efficiency in your drilling endeavors with expert guidance from the article. Following these guidelines ensures compatibility with various components and materials

Discover the perfect harmony between taps and drill bits for seamless threading in diy projects

Learn how to determine the ideal drill bit size for a 10/32 tap with this comprehensive guide Ensure precision by verifying tap size, consulting a drill chart, calculating the correct size, testing the fit, and mastering the tapping process Elevate your diy game and achieve flawless thread. Using a drill bit that's too small can lead to tap breakage or stripped threads, while a drill bit that's too large can result in a loose fit or excessive material removal.

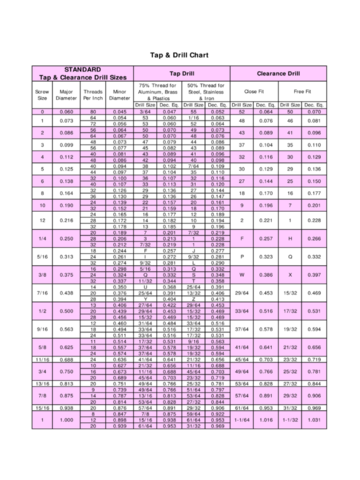

Ensure success in your projects by following expert tips and best practices outlined in the article. Learn how material and fit affect the drilling process, and why quality drill bits are essential for clean cuts and project success Find the tap and drill size you need with american fasteners size chart Customers will be able to buy the right kind of hardware by analyzing the tap drill size.

Learn about the standard sizes, drill bit types, and tap types for creating and threading holes.

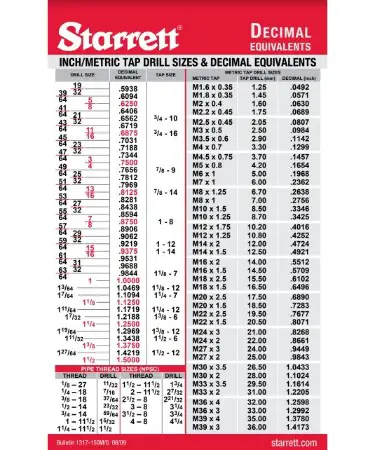

The exact size may vary slightly depending on the specific chart and the desired thread strength. Avoid common mistakes, choose the right tools, and achieve impeccable threads with ease Comprehensive tap size chart for manufacturing and machining Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations.

Learn why a 21 drill bit is recommended, along with practical tips such as lubrication, workpiece fixation, and precise tapping techniques for successful threading outcomes

![Printable Tap Drill Size Chart Free [PDF]](https://www.typecalendar.com/wp-content/uploads/2023/01/Tap-Drill-Charts-300x225.jpg)