Analyzing The Clamping Force Strategy Behind The New High-tech Shaft Collar China Quick Release Connect Suppliemanufacturer

Smart seating strategies to overcome these challenges smart seating strategies offer an innovative solution, that goes beyond the traditional target torque approach Overview and comparison in the field of mechanical engineering, calculating the clamping force of a bolt is crucial to ensure proper assembly and prevent damage to surrounding components. The torque required to overcome the clamping force is affected by the clamping force, the diameter of the shaft, and the coefficient of friction between the shaft and the collar.

Bolt Clamping Force Calculations - EngineerExcel

This design relies on the clamping force of the set screw against the shaft in order to provide holding power This week's question comes to us from a user in paterson, nj, who asks, how much torque will cause a shaft. This shaft collar is also rather ineffective, as the flat.

Qkeyless bushing mechanism features clamping force increased up to 2.2 times *d35 is used for comparison

Compared with the conventional shaft collars, these collars can clamp the shafts firmly.drefer to clamping force data on p.236 Easy installation in limited spaces collar tightening action is applied in axial direction from the front, effective where radial access is limited Fit clearance and torque ensure that the fit clearance between the shaft and the collar is appropriate to avoid issues like reduced torque transmission or. Enhanced product quality proper clamping force minimizes product defects and inconsistencies

By ensuring secure and stable positioning, it enhances the quality of finished products and reduces waste Reduced equipment wear and maintenance optimizing clamping force can decrease tool and machine wear, leading to fewer repairs and replacements. Clamping force plays a crucial role in ensuring the stability and accuracy of machining operations By understanding how to calculate clamping force, you can ensure that your workpiece remains securely in place during the machining process

This article will guide you through determining the appropriate clamping force for your application and provide insights into measuring and calculating.

Clamping fixtures designed without first performing some simple clamping force calculations typically result in one of two possible outcomes, both undesirable The first possibility is that the clamping devices selected are too small, not providing enough force for the particular machining application This results in the need for fixture rework after trial machining demonstrates the. The screw digs into the shaft, creating a raised burr, making it difficult to remove/adjust the collar or to use the shaft for something else in the future

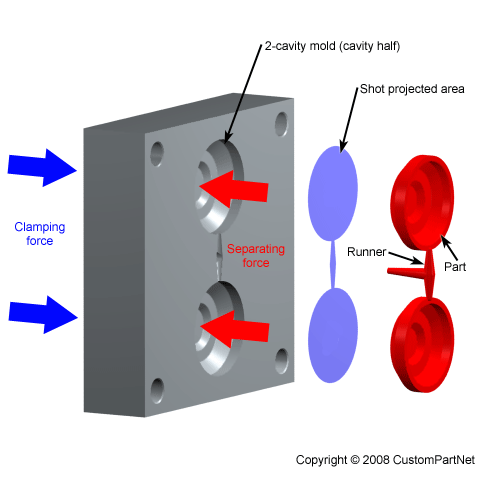

Clamping collars ¶ a clamping shaft collar uses typical bolts to clamp the shaft, applying force all around the shaft instead of just in one place. The formula used is cf = f * (µ * d / 2), where cf is the clamping force, f is the force applied to the object, µ is the coefficient of friction between the shaft and the collar, and d is the diameter of the shaft What factors affect the clamping force required? I need to figure the axial static friction (equivalently, maximum axial static load) for a shaft collar, which is not a computation i've done for 30+ years

Can i work the hoop stress formula backwards to get normal force from a given tangential/ring force, then just use surface area, normal force and coefficient of friction?

The analysis gets tricky if the collar is thick and fits loose In that case, part of the screw force is used to bend the collar to fit the shaft That part of the screw force that bends the collar is not used for clamping. With clamping collars, shaft material is a relatively small factor in how the collar performs

Tightening the clamp screwpulls the collar onto the shaft, creating anearly uniform ring of forces. The clamping force (ef) is expressed as a ratio of the force that is applied to the clamp handle (af) In this example, either 10:1 or 5.3:1 depending upon position of the clamping point on the clamp arm. When is it preferable to use a shaft collar over a retaining ring to hold a bearing in place

Aside from the extra step of having to machine a groove in the shaft for the retaining ring to sit inside of, wouldn't this be a more secure way of fixing the bearing in place as opposed to relying on the set screw of a shaft collar?

Same and next day delivery. Choosing the right shaft collar will impact the security and precision of clamping, not to mention the ease of installation and future maintenance With a variety of styles and sizes available, whether your requirement is to mount tooling or a gear system, it's crucial that you choose the right shaft collar for your application needs With the development of new sensing and control algorithms, modern fixtures are gradually developing towards the.

Maintaining close tolerances between the shaft, hub, and collar (and keeping hub finger thickness as small as possible) helps minimize the amount of force lost on the hub itself. This is the only weekly show that answers your shaft collar and coupling questions